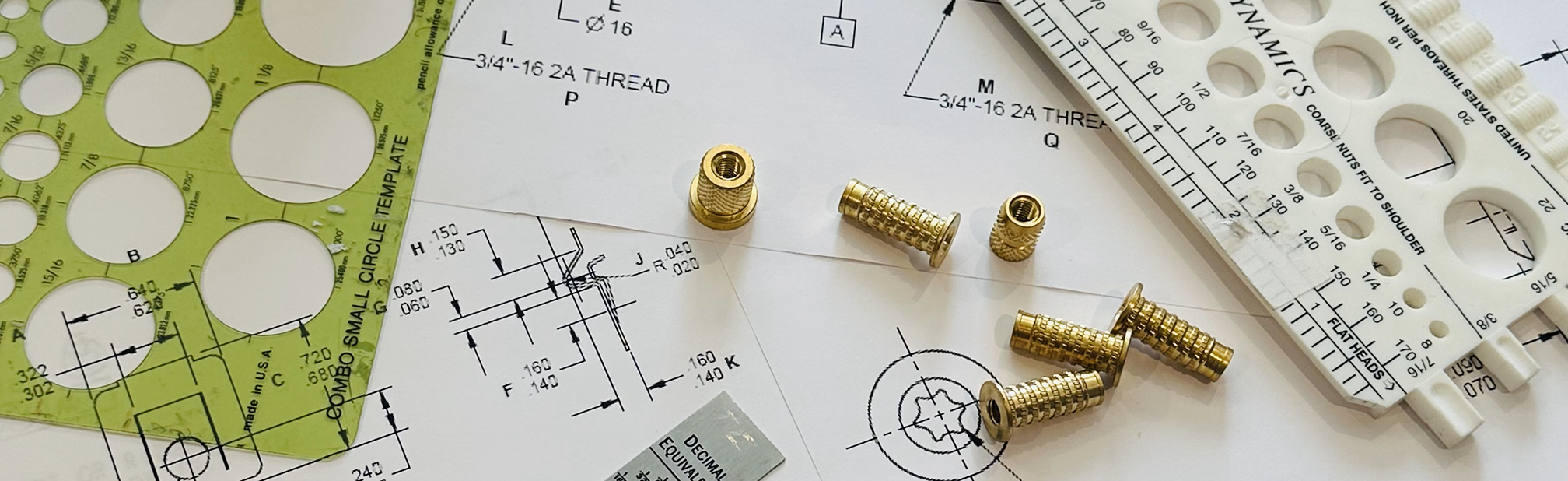

As car designers accelerate the integration of lightweight materials into vehicle designs, collaboration between plastics and fastener engineers has become an imperative. Nowhere is this more evident than during the prototyping and pre-production stages, where fastener choices can significantly influence part performance, manufacturability, and long-term durability. When fastener integration is

automotive

How do threaded inserts help automakers meet CAFE standards?

How custom components can help enhance durability in automotive assemblies while helping achieve bigger goals like emission standards for automakers In 2024, the CAFE standards for passenger cars stand at 54.5 MPG and are set to increase at 2% year over year for model year 2027 through 2031. Those kinds

The Rise of Lightweight Fasteners: Meeting the Demands of EV and Aerospace Sectors

Why Fasteners Matter More Than Ever in Lightweighting Strategies As electric vehicles (EVs) and aerospace applications push the boundaries of lightweight design, every gram counts in modern designs. Engineers in these sectors know that fasteners – while often overlooked – can collectively contribute significant mass to modern designs. With automotive

Plastics quickly making their way into automotive engine bays

Over the past decade, plastics and forms of nylon are quickly replacing their ferrous counterparts as the material of choice under the hood of cars and trucks all over the world. How can this be? Conventional wisdom would tell you that the high temperature and high stress environment of an