If you’re designing plastic assemblies that need to be taken apart and reassembled, you already understand that standard plastic threads simply won’t cut it. But understanding why threaded inserts are not just beneficial, but actually critical requires looking at the fundamental material science challenges that plastics present for threaded connections.

How Do Load Paths Affect the Performance of Threaded Inserts in Plastics?

When plastics engineers think about threaded inserts, the focus often goes straight to the insert itself, looking at attributes such as knurl pattern, installation method and material selection. But here’s what gets overlooked: the insert is only as good as the load path supporting it. A perfectly specified insert installed

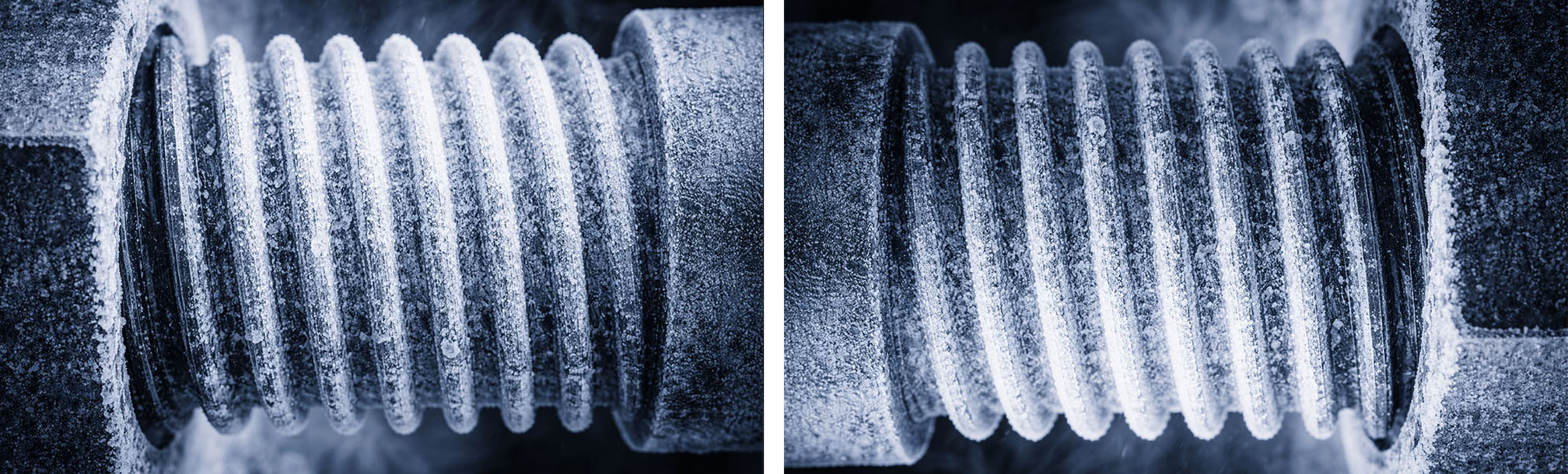

How Does Thermal Cycling Affect Threaded Inserts in Automotive Plastics?

If you’re a plastics engineer working on automotive applications, thermal cycling is undoubtedly a four-letter word in your world. After all, it’s one of the most punishing environments your components will face. In addition, it places stress1 on not only your plastic and composite parts, but also places strain on

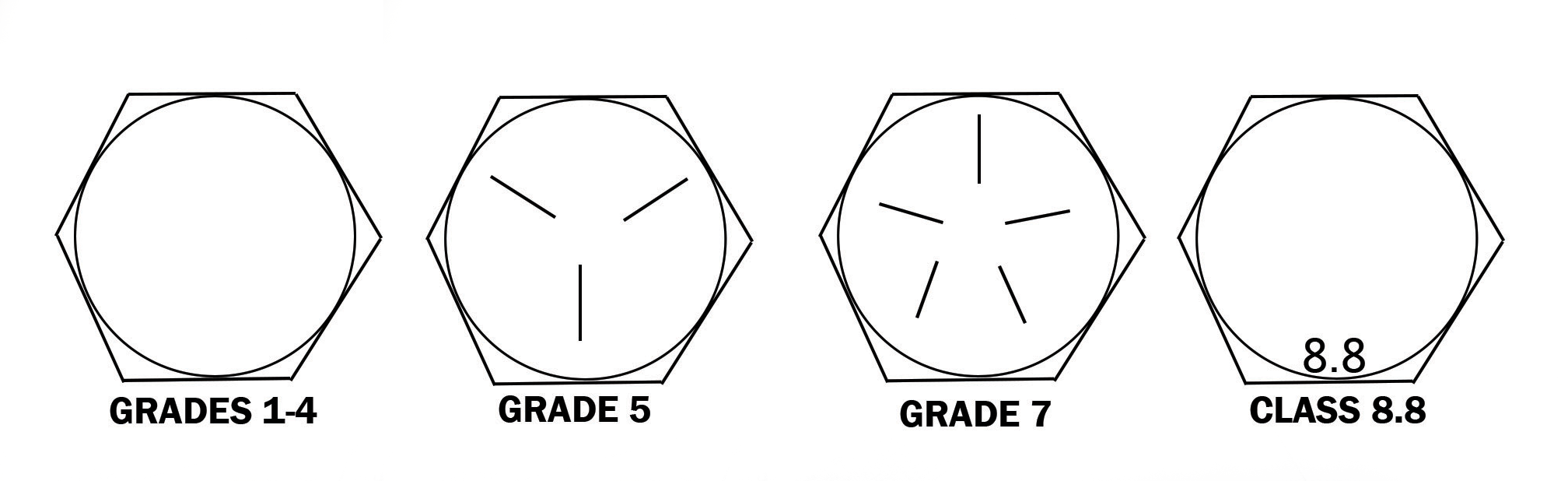

Understanding Automotive Bolt Grades and Classes

How They’re Determined by the SAE, and How They’re Identified by Markings on the Fastener Head Automotive bolted joints operate under demanding cyclic loads, high temperatures, and increasingly lightweight designs. As a result, understanding bolt grades – and the standards behind them-is essential for fastener engineers working in OEM, Tier

How Do Inserts Perform in Carbon Fiber Composites?

Carbon fiber reinforced polymers (CFRP) have transformed aerospace, automotive, and high-performance applications by delivering exceptional strength-to-weight ratios and fatigue resistance. But how do you create reliable threaded connections in a material that’s fundamentally different from the metals we’ve been fastening for over a century? Threaded inserts. However, their performance in

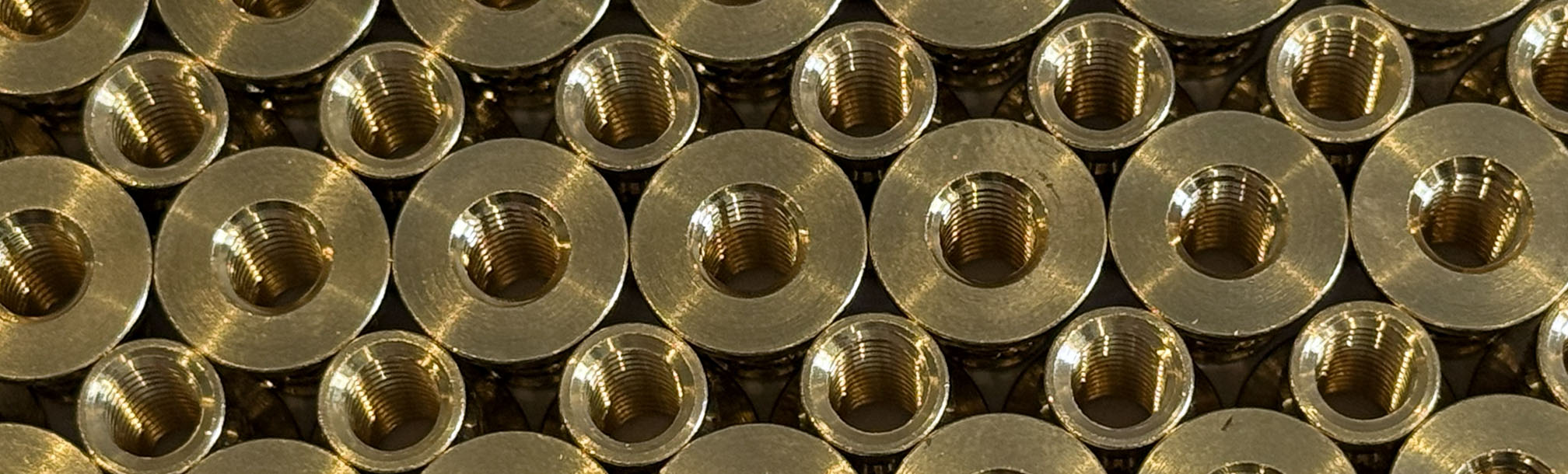

What Are the Key Differences Between Brass, Steel, and Plastic Threaded Inserts, and When Should You Use Each Material?

When purchasing threaded inserts for plastic assemblies, the material choice directly impacts performance, cost, and reliability. While we’ve litigated this topic before, we keep seeing additional interest in our data, we thought we might provide something a little easier to digest about threaded inserts. Brass absolutely dominates the market. We’re

ASTM vs. ISO vs. SAE vs. JIS Fastener Standards: What’s the Difference?

When specifying fasteners for engineering projects, understanding the differences between ASTM, ISO, SAE, and JIS standards is critical. These four organizations govern the majority of fastener specifications used worldwide, but each has distinct origins, measurement systems, applications, and grading methods. Here’s what engineers need to know to navigate these standards

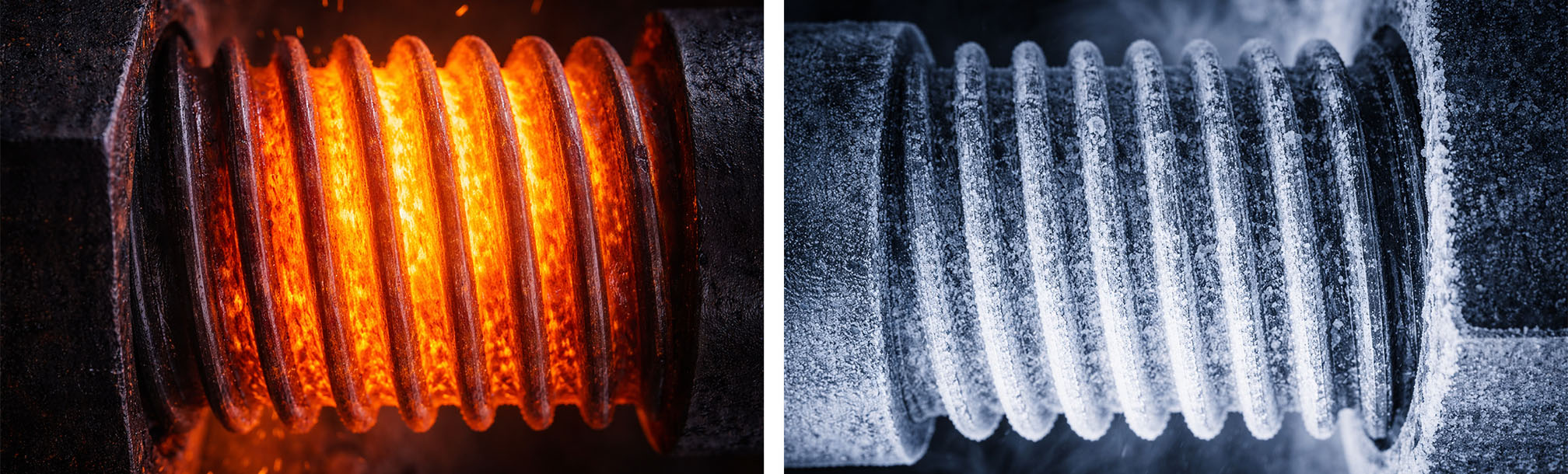

When Is Hot Forging Better Than Cold Heading for Fasteners?

OK, we’ve asked the basic questions of what hot forging and cold heading are – now it’s time to get down to the nitty gritty. Which one of these processes should you choose? For fastener engineers, selecting the right manufacturing process can significantly impact product performance, production costs, and lead

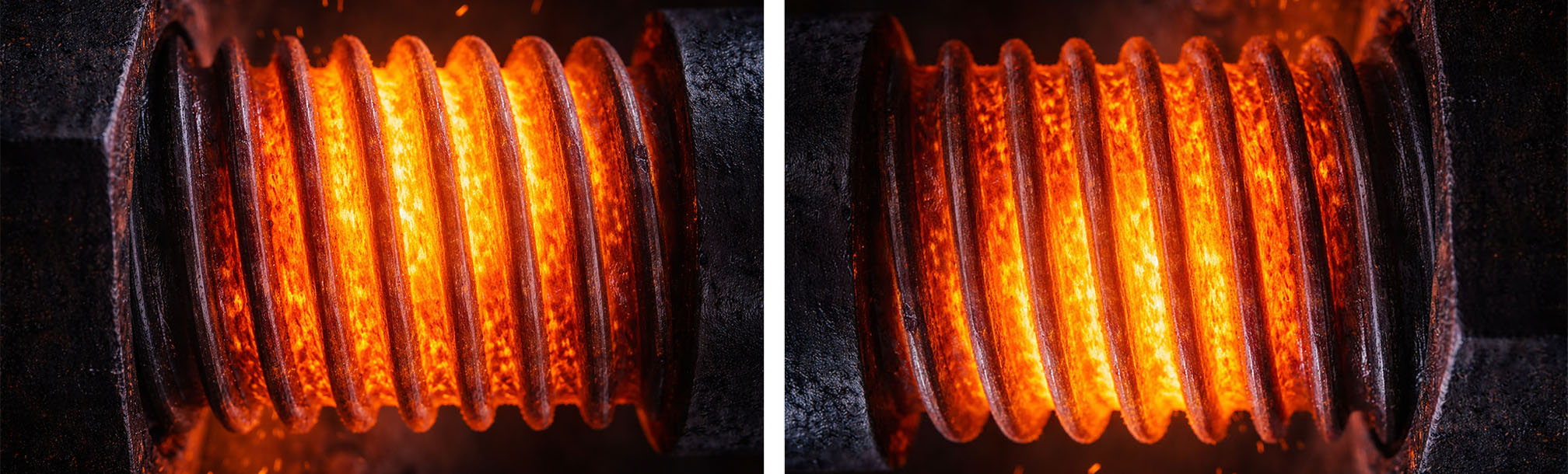

What is Hot Forging?

Hot forging represents a critical manufacturing process for fasteners exceeding M36 diameter and for applications involving high-performance materials such as titanium alloys in aerospace applications. A comprehensive understanding of hot forging is essential for informed design decisions in fastener engineering. Technical Definition Hot forging is the plastic deformation of metal

What Is Cold Heading? A Complete Beginner’s Guide for Engineers

When you’re designing fasteners for potential project, understanding the manufacturing process can significantly impact your design decisions, costs, and product performance. One of these fastener manufacturing processes, cold heading – also called cold forming – is one of the most efficient and reliable manufacturing processes for producing high-strength fasteners and