OK, we’ve asked the basic questions of what hot forging and cold heading are – now it’s time to get down to the nitty gritty. Which one of these processes should you choose? For fastener engineers, selecting the right manufacturing process can significantly impact product performance, production costs, and lead times. While cold heading dominates high-volume fastener production, hot forging remains the superior choice for specific applications. Understanding when to specify hot forging over other fastener production methods like cold heading is essential for optimizing your fastener design and manufacturing strategy.

Understanding the Fundamental Difference between cold heading and hot forging

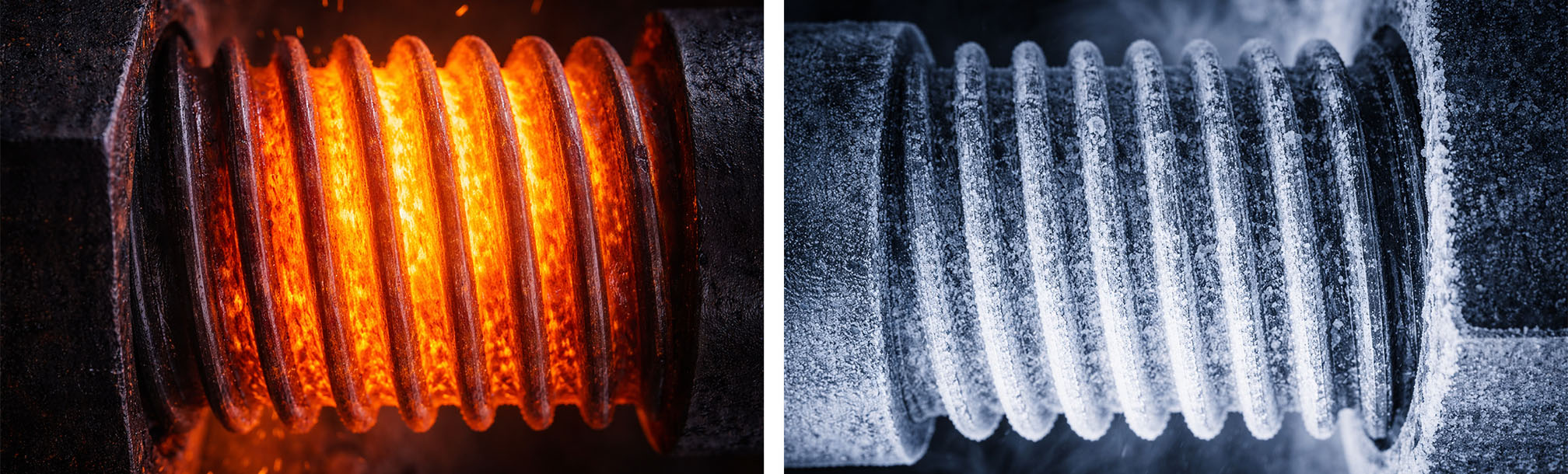

Cold heading shapes metal at room temperature through high-pressure dies. while hot forging heats metal above its recrystallization temperature – typically between 650°C to 1,300°C (approximately 1,200°F to 2,300°F) for steels – prior to deformation. From a metallurgical standpoint, hot forging is defined as the plastic deformation of metal at 75% of its melting temperature1. This specific temperature and strain rate is chosen so that recrystallization occurs simultaneously with deformation, thus avoiding strain hardening.

When is Hot Forging the Better Choice?

1. Large Diameter Fasteners (Above M36 / 1⅛”)

Hot forging typically becomes necessary for larger fasteners. As diameter increases, the force required for cold heading increases rapidly. Cold heading is primarily limited to fasteners under M36 diameter in commercial applications, while hot forging can handle diameters ranging from roughly 13mm to 101mm and beyond. British Standards (BS 4190:2001) specify that bolts and screws may be produced by cold forging or hot forging at the discretion of the manufacturer2. In practice, most manufacturers prefer that hot forging be deployed for diameters above M36 due to forming loads, tooling costs and durability, and process stability.

As fastener diameter increases, the pressure needed to shape the material rises significantly, making hot forging more practical for large fasteners even though machines capable of cold heading large sizes exist.

2. Difficult-to-Form Materials

Some materials and harder alloys simply won’t cold form effectively but will form at recrystallization temperatures. Hot forging is essential when working with metals such as titanium, certain nickel alloys and specific high-strength steels.

Titanium and titanium alloys: Research published in materials engineering journals indicates that titanium requires heating to achieve proper malleability. The optimal forging temperature for titanium alloys generally falls within 870°C to 1,100°C (1,598°F to 2,012°F), with Ti-6Al-4V—the most commonly-used titanium alloy—typically forged around 925-955°C. Warm forming of titanium sheet is typically done at temperatures around 650°C (1,200°F), while cold workability is limited due to titanium’s high strength at room temperature.

High-strength tool steels: Materials that are too hard or brittle for cold heading benefit from the increased malleability that elevated temperatures provide.

3. Complex Head Geometries

Hot forging excels at creating intricate shapes but requires some secondary finishing that cold heading does not. The increased material malleability at elevated temperatures enables formation of complex head configurations and specialized geometries where the die would crack or fail under cold heading operations. Metals become highly malleable during the hot forging process, allowing complex shapes to be formed with relatively low force. The process refines grain structure, resulting in stronger and more durable components.

4. Extremely Long Lengths

Extended fastener lengths and larger fasteners generally favor hot forging. When producing fasteners with extreme lengths – particularly those exceeding 200-300mm in length – hot forging provides better material flow and reduces the risk of buckling or dimensional inconsistencies.

5. Low to Medium Production Volumes

Cold forging also requires relatively high setup and tooling costs for shorter runs – sometimes in the thousands or even the tens of thousands of US dollars depending on complexity. Hot forging may be considered a good alternative to avoid these production costs. In many cases, cold forging die costs begin to break-even only at volumes of approximately 5,000 pieces or more, making hot forging attractive for shorter production runs.

Trade-offs to Consider

While hot forging offers clear advantages in these scenarios, engineers should be aware of the trade-offs:

Dimensional Tolerances

Cold heading provides superior dimensional precision. Cold heading is well-known for its superior dimensional accuracy because the process occurs at room temperature and does not significantly alter the material’s structure through thermal expansion. Meanwhile, hot-forged fasteners generally have looser tolerances and often require secondary machining operations to achieve final specifications.

Surface Finish

Hot forging typically produces oxide scale on the component surface that must be removed through shot blasting or other finishing operations. To prevent gas contamination which occurs during hot forging (O₂, H₂, or N₂ contamination), it’s possible to protect components by glass coating, protective lubricants or controlled atmosphere within vacuum heating furnaces.

Production Speed

Cold heading is significantly faster for high-volume production. Cold heading generally delivers better results for high-volume, standardized fasteners, while hot forging is reserved for large, specialized components with demanding metallurgical requirements.

Energy Costs

Hot forging requires substantial energy for heating furnaces or induction systems. The process is performed at the highest temperature which does not destroy the metallurgical features of the considered alloy. As a result, cold forging is more energy-efficient than hot forging since it doesn’t require extra energy to heat material before production.

Making the Right Choice Between Hot Forging and Cold Heading

The decision between hot forging and cold heading should be based on a comprehensive evaluation of your project requirements:

Choose hot forging when:

- Fastener diameter exceeds approximately M36 (1⅛”)

- Working with difficult materials like titanium, Inconel, or high-strength tool steels

- Complex head geometries are required

- Production volumes are low to medium

- Extreme lengths are specified

Choose cold heading when:

- High-volume production is required (typically 5,000-10,000+ pieces)

- Tight dimensional tolerances are critical

- Working with ductile materials like low to medium carbon steel, austenitic stainless steel, or aluminum

- Superior surface finish is needed without secondary operations

- Fastener diameters are under M36 (1⅛”)

Conclusion

Hot forging remains an essential manufacturing process for specific fastener applications where size, material properties, geometry, or production volume make cold heading impractical or impossible. By understanding the strengths and limitations of each process, engineers can make informed decisions that optimize performance, cost, and manufacturability for their specific application requirements.

For critical applications requiring large diameters, exotic materials, or complex geometries, hot forging delivers the metallurgical properties and forming capabilities that cold heading simply cannot match. The process’s ability to accommodate difficult-to-form alloys, and handle complex shapes makes it indispensable for aerospace, medical, and other high-performance applications.

Where does CFI fit in?

For over 30 years, Components for Industry (CFI) has been a worldwide provider in cold headed and hot forged industrial components. Ready to discuss whether hot forging or cold heading is right for your project? Contact CFI at 847-918-0333 or sales@componentsforindustry.com today for a feasibility assessment and quote.