Hot forging represents a critical manufacturing process for fasteners exceeding M36 diameter and for applications involving high-performance materials such as titanium alloys in aerospace applications. A comprehensive understanding of hot forging is essential for informed design decisions in fastener engineering.

Technical Definition

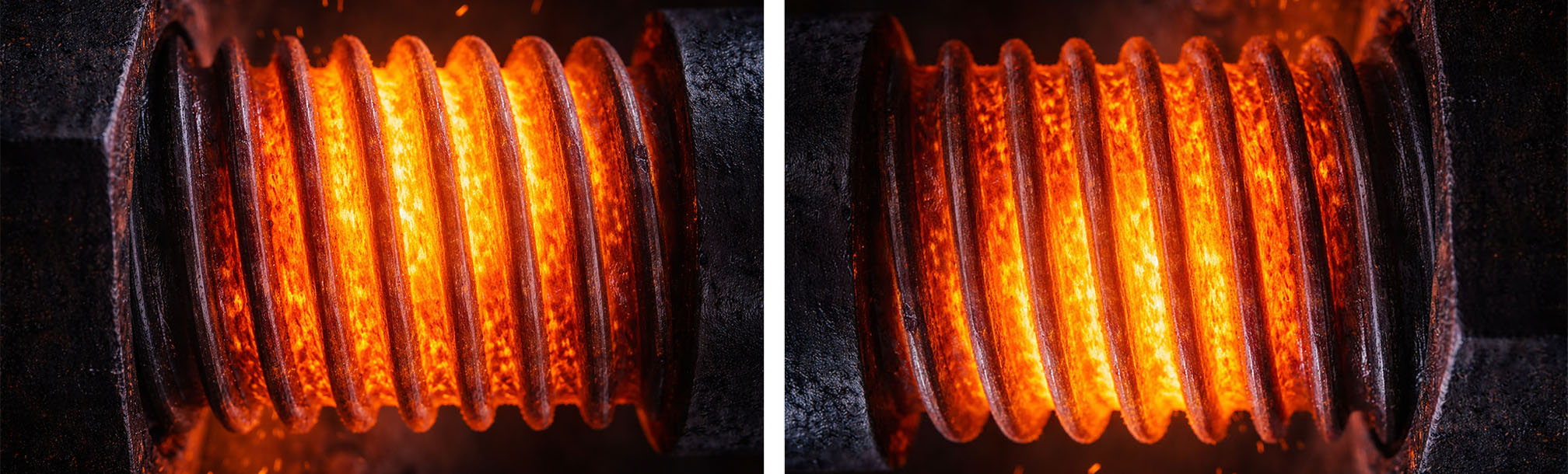

Hot forging is the plastic deformation of metal above its recrystallization temperature, enabling the material to recrystallize continuously during forming. This prevents strain hardening, maintaining low yield strength and high ductility, which allows extensive deformation without embrittlement or cracking.

Temperature Parameters

Temperature control is the most critical parameter in hot forging operations. The process requires heating metal above its recrystallization temperature, typically between 0.3 to 0.4 times the melting point for pure metals, and approximately 0.5 times the melting point for alloys. As a general guideline, the lower temperature limit is approximately 60% of the melting temperature on an absolute scale1.

Standard temperature ranges for common fastener materials include:

- Steel: 700°C to 1,250°C (1,292°F to 2,282°F)

- Aluminum alloys: 300°C to 550°C (572°F to 1,022°F)

- Titanium alloys: 750°C to 1,040°C (1,382°F to 1,904°F)

- Copper alloys: 700°C to 800°C (1,292°F to 1,472°F)22

These temperature ranges represent the optimal processing window where material workability is maximized without compromising structural integrity or inducing excessive grain growth. Deviation from these parameters results in process defects and compromised material properties.

Process Description

Material Heating

The hot forging process commences with a cast ingot that is heated to its plastic deformation temperature in specialized furnaces. Precise temperature control during this phase is critical, as it directly influences both material formability and final component properties.

Die Preparation

Along with material heating, forging dies must also be prepared. Hot forging dies are subjected to severe thermal cycling and mechanical loading conditions, necessitating their manufacture from heat-resistant tool steels specifically engineered for high-temperature applications. Dies are custom-designed to correspond with specific part geometries.

Forging Operation

Upon reaching the target temperature, the workpiece is rapidly transferred to the forging equipment to minimize heat loss. The metal is shaped under substantial pressure using custom molds. Equipment selection depends on component size and geometric complexity:

- Drop hammers and power drop hammers

- Hydraulic presses

- Mechanical presses

- Screw presses

Controlled Cooling

Following deformation, the component undergoes a controlled cooling process, typically through quenching, which establishes final shape and enhances material properties. Cooling must be executed with precision to prevent warpage. Excessive cooling rates result in dimensional distortion and component rejection.

Finishing Operations

Hot-forged components typically require secondary operations including trimming, machining, or heat treatment to achieve final specifications and optimize material characteristics.

Metallurgical Transformations

During hot forging, the original cast, coarse grain structure is refined through controlled deformation and size reduction of the ingot. The forging process disrupts the existing grain structure and replaces it with finer, more uniform grains. This metallurgical transformation fundamentally enhances mechanical properties, often resulting in superior performance compared to machined or cast alternatives.

Additionally, hot working reorients inclusions within the material matrix. In the as-cast condition, inclusions exhibit random orientation. However, during hot working, these inclusions align with the material flow, creating directional stringers. This alignment improves mechanical performance in the primary loading direction.

Advantages of Hot Forging

Enhanced Mechanical Properties

Hot forging refines grain structure, producing components with superior strength and durability. The elevated temperature renders the metal highly malleable, enabling complex geometries to be formed with relatively reduced force compared to cold working processes.

Elimination of Strain Hardening

Operating above the recrystallization temperature eliminates strain hardening effects, improving material ductility and toughness3.

Complex Geometry Capabilities

Elevated processing temperatures significantly increase material malleability, enabling the formation of more intricate shapes than achievable through cold forging. This capability is particularly valuable for specialized fastener head configurations or unique thread forms.

Reduced Forming Forces

Higher temperatures make metal more pliable, requiring less force to form. This enables production of larger components impractical for cold heading.

Compatibility with Difficult Materials

Certain materials simply require hot forging processes. Iron and its alloys predominantly utilize hot forging. Similarly, materials commonly specified for demanding applications such as titanium, nickel superalloys, and high-strength tool steels, typically require hot forging for successful forming.

Process Limitations

Dimensional Tolerance and Surface Finish

Hot forging provides lower dimensional precision compared to cold heading processes, and surface finish is characteristically rougher. Secondary machining operations are typically required to achieve final dimensional specifications. Applications requiring tight as-forged tolerances may necessitate alternative manufacturing processes.

Surface Degradation

Workpieces are susceptible to oxidation, decarburization, and thermal damage. To prevent gas contamination from oxygen, hydrogen, or nitrogen, manufacturers employ protective glass coatings or utilize controlled atmospheres (inert gas environments) within heating furnaces. These protective measures increase processing costs.

Energy Requirements

Hot forging demands substantial energy for furnace heating and temperature maintenance throughout the process. This represents a significant operational cost compared to cold forming methods, which is reflected in component pricing.

Die Degradation

Forging dies experience severe thermal cycling and mechanical loading, leading to cracking, plastic deformation, thermal fatigue, and wear. Die life is reduced compared to cold heading dies, impacting tooling costs and production lead times.

Cooling Process Complexity

The cooling phase requires careful control, as cooling rate influences final mechanical properties. Slow cooling reduces internal stresses while rapid cooling enhances hardness. Improper cooling parameters result in component rejection.

Isothermal Forging

Isothermal forging represents a specialized variant in which both the workpiece and die are heated to identical temperatures, with adiabatic heating assisting material deformation under highly controlled strain rates.

Isothermal forging is predominantly conducted on superalloys in vacuum or highly controlled atmospheres to prevent oxidation. This technique is particularly valuable for aerospace applications involving titanium alloys and nickel-based superalloys where precise metallurgical control is required. While expensive, isothermal forging may be the only viable method to achieve specific material specifications.

Temperature Management Considerations

Approximately 90% of the energy imparted to the workpiece converts to heat. However, the majority of this thermal energy is lost through the component surface to the cooler tooling, creating temperature gradients wherein thinner sections cool more rapidly than thicker sections.

Heating the tooling minimizes these gradients, but elevated tooling temperatures reduce tool life. As a compromise, hot working tooling is commonly heated to 500–850°F (260–454°C). Temperature control throughout the process represents the most critical aspect of any hot working operation.

Applications in Fastener Manufacturing

Hot forging is indicated for fastener applications under the following conditions:

- Large diameter fasteners (typically exceeding M36 or 1⅛ inch diameter) where cold heading forces become impractical

- High-strength alloy bolts manufactured from materials such as 4340, 8620, or Inconel, which resist cold forming

- Titanium fasteners for aerospace and medical applications, as titanium requires elevated temperatures for workability

- Complex head geometries unachievable through cold heading, including custom profiles or integrated features

- Extended length fasteners where cold heading introduces risk of buckling or dimensional deviation, as material flow is superior in hot forging

- Low to medium production volumes where cold heading tooling costs cannot be economically justified, as hot forging dies are less expensive

Conclusion

Hot forging represents a fundamentally distinct manufacturing process that provides capabilities unavailable through alternative methods. By heating metal above its recrystallization temperature and controlling the deformation process, manufacturers can produce components with enhanced mechanical properties, refined grain structures, and complex geometries.

When specifying fasteners, hot forging should be considered for large sizes, difficult-to-form materials, complex geometries, or when production volumes do not justify cold heading tooling investment. While the process has limitations including dimensional tolerances, surface finish quality, and energy costs, for certain applications, hot forging represents not merely an optimal solution, but the only practical manufacturing method.

As engineering assemblies increasingly demand exotic materials and higher performance specifications, hot forging remains an essential manufacturing capability. Understanding the appropriate application of this process distinguishes competent fastener specification from comprehensive fastener engineering.

Where does CFI fit in?

For over 30 years, Components for Industry (CFI) has been a worldwide provider in hot forged industrial components. Ready to discuss whether hot forging or cold heading is right for your project? Contact CFI at 847-918-0333 or sales@componentsforindustry.com today for a feasibility assessment and quote.

Sources

- Wikipedia. “Hot working.” https://en.wikipedia.org/wiki/Hot_working ↩︎

- Farinia Group. “The Hot Forging Manufacturing Process and Its Undoubted Advantages.” https://www.farinia.com/blog/hot-forging-manufacturing-process-and-its-undoubted-advantages ↩︎

- Bonanomi. “Hot Forging: What It Is and Its Characteristics.” https://www.bonanomi.it/en/hot-forging-how-it-works-and-its-process-characteristics/ ↩︎