When you’re designing fasteners for potential project, understanding the manufacturing process can significantly impact your design decisions, costs, and product performance. One of these fastener manufacturing processes, cold heading – also called cold forming – is one of the most efficient and reliable manufacturing processes for producing high-strength fasteners and precision-formed components. We wanted to go in-depth on the cold heading process so you could weigh the pros and cons on whether you should use this production technique or another such as casting, machining, powder metallurgy, or additive manufacturing.

Whether you’re optimizing component designs or looking for ways to reduce manufacturing costs – or if you’re deciding between cold heading and hot forging – this guide will start you on the path of understanding what cold heading can deliver for your fastener engineering needs.

What Is Cold Heading?

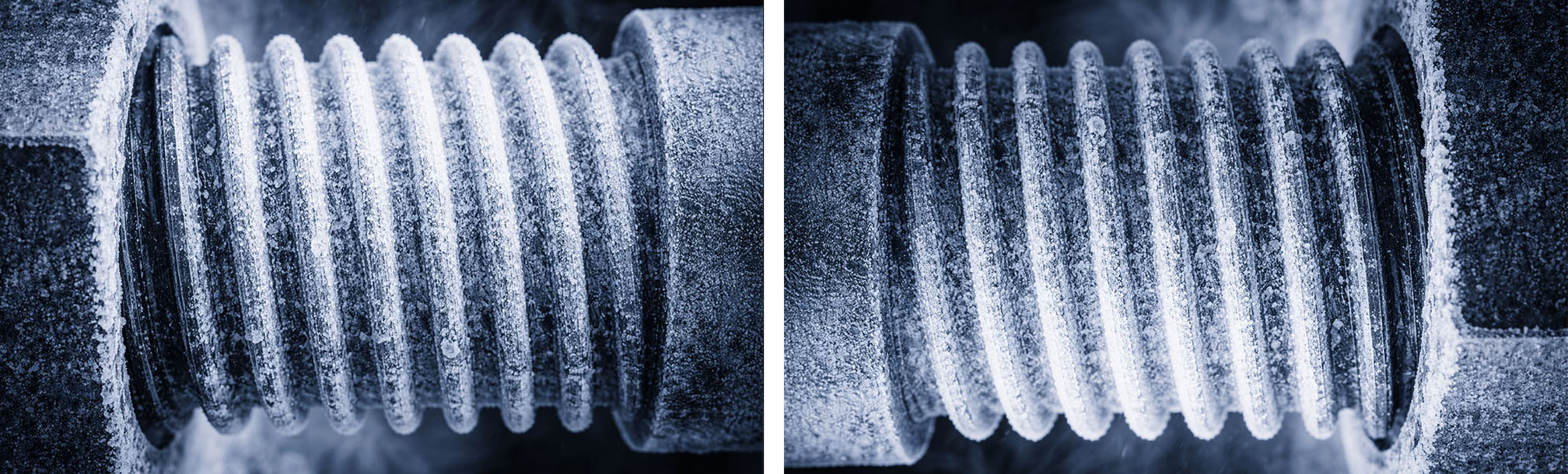

Cold heading, also known as cold forming or cold forging, is a metal forming process that shapes metal wire or rod at temperatures much lower than hot forging (typically 59°F or 392°F – 15°C-200°C) using high-pressure dies, hammers and punches.

Cold heading machines are fed wire stock; cut the wire’s material to length, and shape this material using these dies, hammers and punches through plastic deformation. During this cold heading process, the metal is never heated or machined, but formed into its eventual shape at room temperature – under the metal’s recrystallization point. On the flip side, the hot forging process requires heating the metal to temperatures between 1,200°F and 2,300°F (650°C to 1,300°C), raising the temperature over the metal’s recrystallization point, making the material easier to shape to its eventual form.

The cold heading process is considered extremely efficient because no material is removed from the original metal wire stock. Because no material is removed, cold heading is highly efficient and produces minimal waste, making it an ideal process for high-volume fastener production.

The Basic Cold Heading Process

Here’s how a typical cold heading operation works:

Step 1: Wire Preparation – In order to create a proper slug, coiled wire stock is drawn to the precise diameter needed. This wire is then cleaned and prepped to remove any surface contaminants, lubricants or scale. This surface preparation ensures smooth forming and prevents tool and die wear. This prepped wire is then fed into a cold heading machine and sheared to the appropriate blank length to become the starting slug for forming.

Step 2: Forming – The slug is positioned in a die cavity, and one or more punches strike it with extremely high force. These strikes plastically displace the metal into the desired shape of the die. Multi-station heading machines can perform several progressive forming operations such as upsetting, extrusion or trimming in rapid succession.

Step 3: Secondary Operations – Depending on part requirements, additional processes such as thread rolling, heat treatment, or surface finishing may follow. These operations refine mechanical properties, enhance corrosion resistance, or produce features not formed during the initial heading process.

Why Specify Cold Heading for Your Components?

Cold heading offers several compelling advantages that translate directly to better-performing parts, faster production, and lower overall cost compared to other production methods such as hot forging, machining, casting, stamping and wire forming.

Material Efficiency – Since the process forms material rather than cutting it, there’s virtually no material waste. The metal is simply redistributed, not removed as chips or swarf. This efficiency can drastically reduce your material costs on high-volume production runs. Cold heading is especially efficient compared to machining, where metal cutting operations waste both material and time on large runs.

Superior Strength – Cold working the metal increases its strength by up to 50% over hot worked steel through work hardening. The uninterrupted grain flow also enhances the part’s mechanical properties compared to machined components where grain structure is severed. This means your parts can be lighter or handle higher loads.

High Production Speed – Modern cold heading machines can produce parts up to 20x the rate of standard screw machines (20 parts per minute vs. 400 parts per minute). This making the cold heading process ideal when you need thousands or millions of components with quick turnaround times.

Cost-Effectiveness – The combination of material efficiency, high speed, and minimal secondary operations results in very low per-part costs at volume production. For the right component application, cold heading can dramatically reduce your production costs.

Consistent Quality – While initial tooling costs are relatively high, once that tooling is properly set up, cold heading produces highly repeatable parts with tight tolerances and excellent surface finish. This reduces QC concerns as well as rejection rates, making cold heading an ideal production method.

Common Applications

Cold heading is the dominant manufacturing method for:

- Bolts, screws, and threaded fasteners of all types

- Rivets and solid pins

- Automotive components (wheel studs, brake system parts)

- Aerospace fasteners requiring high strength-to-weight ratios

- Electrical contacts and terminals

- Specialty fasteners with complex head geometries

If your project requires any of these components, cold heading is likely the most economical choice.

Materials Suitable for Cold Heading

Not all alloys respond well to cold heading. The material must have sufficient ductility to withstand the plastic deformation without cracking. In fact, even some alloys that can withstand the plastic deformation, like 1215 and 12L14 Stainless Steels, have limitations for critical applications requiring high mechanical properties.

| Metal Alloys Suitable for Cold Heading | ||

| Alloy Designations | Subtype | Characteristics |

| 1008, 1010, 1018, 1020 | Low Carbon Steels | Excellent workability for Cold Heading applications |

| 1035, 1038, 1040, 1045 | Medium Carbon Steels | May require higher forces due to work hardening |

| 4140, 4340, 8620 | Alloy Steels for High Strength | May require higher forces due to work hardening |

| 1215, 12L14 | Machining Grades | Has limitations for critical applications |

| 302, 304, 305, 316 | Austenitic Grades | Excellent for cold formability |

| 410, 430 | Martensitic and Ferritic Grades | More limited formability vs. Austenitic Grades |

| 1100, 2024, 5056, 6061 | Varying grades of workability depending on alloy | |

| C11000 | Electrolytic Tough Pitch Copper | Excellent cold workability |

| C26000 | Cartridge Brass | Excellent cold workability |

| C36000 | Free-Cutting Brass | Moderate to Poor cold workability |

| C51000 | Phosphor Bronze | Good workability |

| C65500 | Silicon Bronze | Excellent workability |

| Monel 400, Inconel 600, 718 | Corrosion-resistant applications | Good to Excellent workability |

When discussing material options with your CFI rep, cold formability is typically characterized by its reduction of area in tensile testing, with higher values indicating better suitability for cold heading.

Design Considerations for Your Parts

If you’re designing parts for cold heading production, keep the following basic guidelines in mind to ensure component manufacturability and cost-effectiveness:

Volume-to-Volume Ratios – Extreme head-to-shank diameter ratios require multiple forming stages, which increases tooling complexity and cost. A general rule of thumb is that the head diameter shouldn’t exceed 2.5 times the shank diameter in a single blow.

Length-to-Diameter Ratios – The blank length should typically not exceed a 3:1 ratio to prevent buckling during forming. If your design requires longer components, appropriate dies can potentially be fashioned.

Material Selection – Choose materials with good cold formability. CFI engineers can recommend specific cold heading quality material grades that will optimize both performance and manufacturability.

Tolerances – While cold heading is precise, understanding which dimensions can be held tightly and which may require secondary operations will help you optimize your specifications and costs.

Tooling Economics – Cold heading requires significant upfront tooling investment, so it’s most economical for production runs in the thousands or even in the millions. We recommend discussing your volume requirements early to ensure cold heading is the right choice for your specific project.

When Should You Consider Alternatives to Cold Heading?

Despite its advantages, cold heading isn’t suitable for every application. Times when alternatives may need to be considered include low volume applications; complex designs; brittle materials; very large parts; and extremely tight tolerances.

Cold heading is typically considered a volume production method due to the high initial tooling costs. As a result, it is uneconomical for prototypes or low-volume production runs under 5,000 pieces. During the prototyping stage or for production runs under 2,500 pieces, machining may be a good alternative to cold heading. In fact, cold heading is typically used for volume production runs over 25,000 pieces11.

Another time to consider alternatives to cold heading is when intricate geometries are involved in your design. Complexity is limited by what can be formed through progressive die strikes and alternative processes such as machining, injection molding, and extrusion.

Cold heading requires significant ductility from its base metals. If these metals are very hard or brittle at room temperature (or close to it), they make for poor candidates for cold heading.

As a result, some metals are simply too brittle or too hard to cold form, including high-carbon steels (above 0.5% carbon), hardened tool steels, cast iron, certain titanium alloys, and many heat-treated materials that lack the ductility needed for plastic deformation without cracking. (See the above chart for suitable metal alloys)

Very large parts may exceed the capacity of available equipment (most cold heading is suited for parts under 6 inches in diameter)

Extremely tight tolerances on certain features may require secondary machining operations, which can reduce the cost advantage.

Cold Heading vs. Other Processes

vs. Machining – At scale, per part, cold heading is indeed faster and creates stronger parts with less waste, but that statement doesn’t tell the whole story. Why? It’s because machining offers more geometric flexibility and lower setup costs for small batches or prototypes. In other words, you machine prototypes; you go to production with cold heading.

vs. Hot Forging – Cold heading produces better surface finish and tighter tolerances without the energy costs of heating, though hot forging can handle much larger parts and less ductile materials.

vs. Stamping – Cold heading excels at creating three-dimensional upset forms and solid parts, while stamping is better for sheet metal and flat components.

A component production partner like CFI can help you evaluate which process best fits your specific requirements. Our sales engineers can help guide you through all of these individual processes so you can choose the best one for your project’s fasteners.

Where does CFI fit in?

For over 30 years, Components for Industry (CFI) has been a worldwide provider in cold headed industrial components. Ready to discuss whether cold heading or hot forging is right for your project? Contact CFI at 847-918-0333 or sales@componentsforindustry.com today for a feasibility assessment and quote.

Sources

- The Nickel Institute. “Cold Forming Stainless Steel Bar and Wire.” https://nickelinstitute.org/media/1647/coldformingstainlesssteelbarandwire_9019_.pdf pg 5 ↩︎