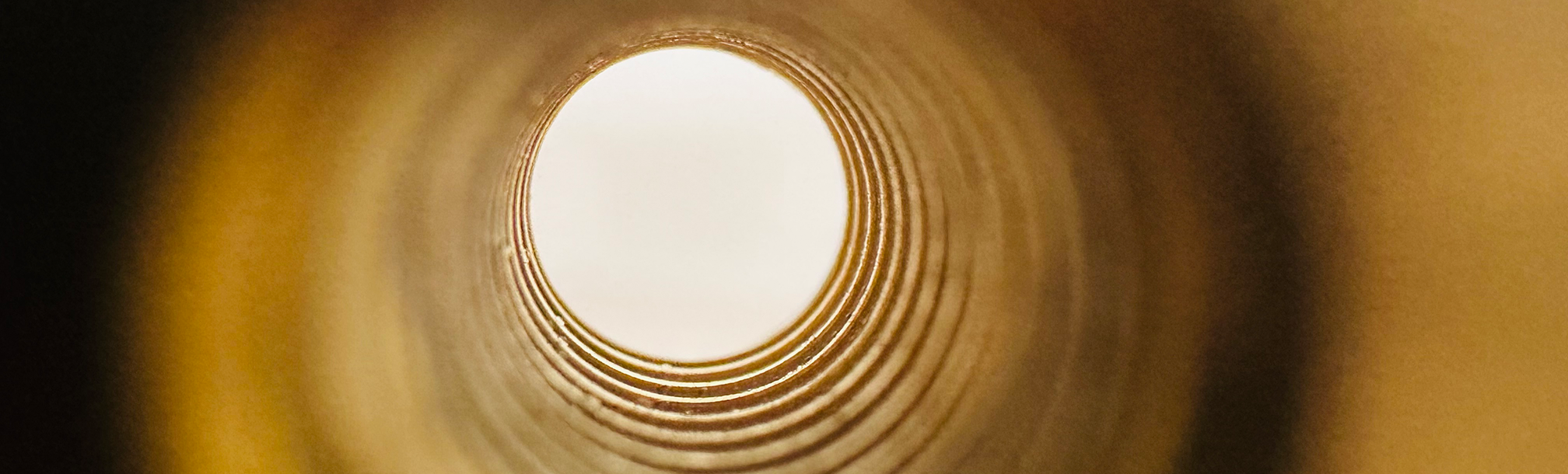

In our previous blog, we covered the basics of threaded inserts and more specifically, brass inserts. However, we only touched upon their use in injection molding applications. As we said in our previous blog, injection molding goes hand-in-hand with brass inserts because inserts offer a strengthened connection between plastics and

Injection Molding

Why choose threaded inserts for your engineering application?

At CFI, we typically engineer custom screws, nuts and bolts for any application, however, our expertise doesn’t end there. Today we will be going over a component called brass inserts. We’ll answer basic questions like what they are, what they do, why they’re often made of brass. In addition, we’ll

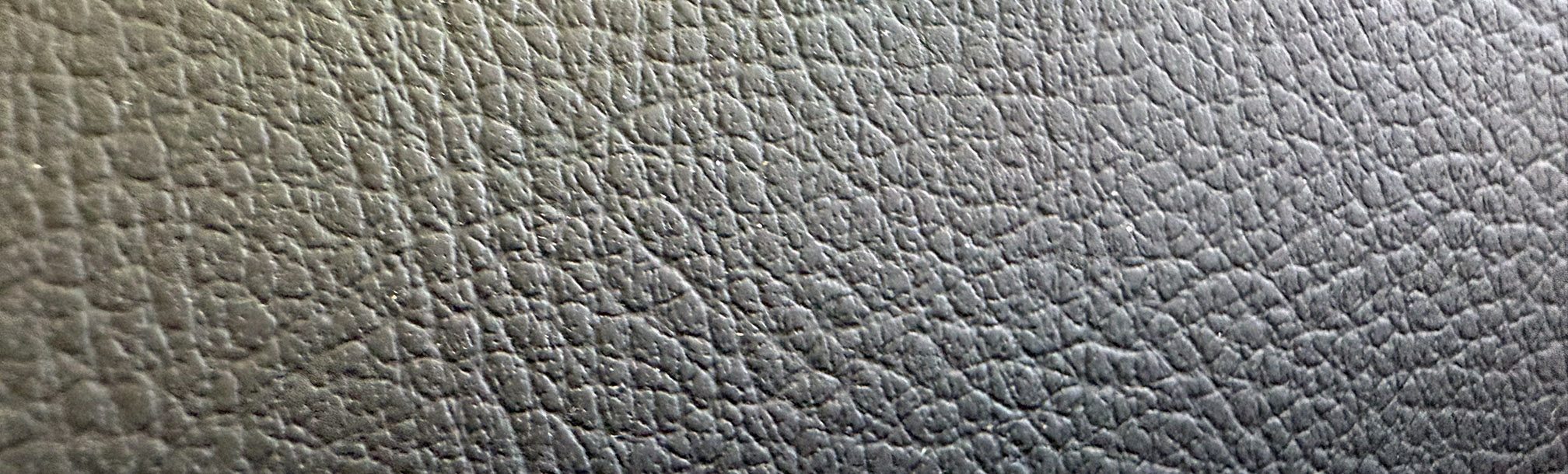

Strength and Aesthetics: Fastener Integration Without Marring Injection-Molded Surfaces

How to Conceal Fasteners Without Compromising Design Strength In automotive industry product design, achieving both strength and aesthetics can be especially challenging. While incorporating fasteners are essential to the end design for reliable assembly, they can leave unsightly cosmetic flaws on injection molded surfaces. However, built from the ground-up with