How to Conceal Fasteners Without Compromising Design Strength In automotive industry product design, achieving both strength and aesthetics can be especially challenging. While incorporating fasteners are essential to the end design for reliable assembly, they can leave unsightly cosmetic flaws on injection molded surfaces. However, built from the ground-up with

fasteners

How to Select Fastener Materials for Extreme Temperature Applications

Extreme temperature environments create unique challenges for fastener selection. Whether designing for automotive underhood components experiencing 300°F heat cycles, aerospace systems operating at cryogenic temperatures below -300°F, or industrial equipment exposed to furnace conditions exceeding 2000°F, proper material selection is critical for safety, reliability, and performance. Here’s what engineers need

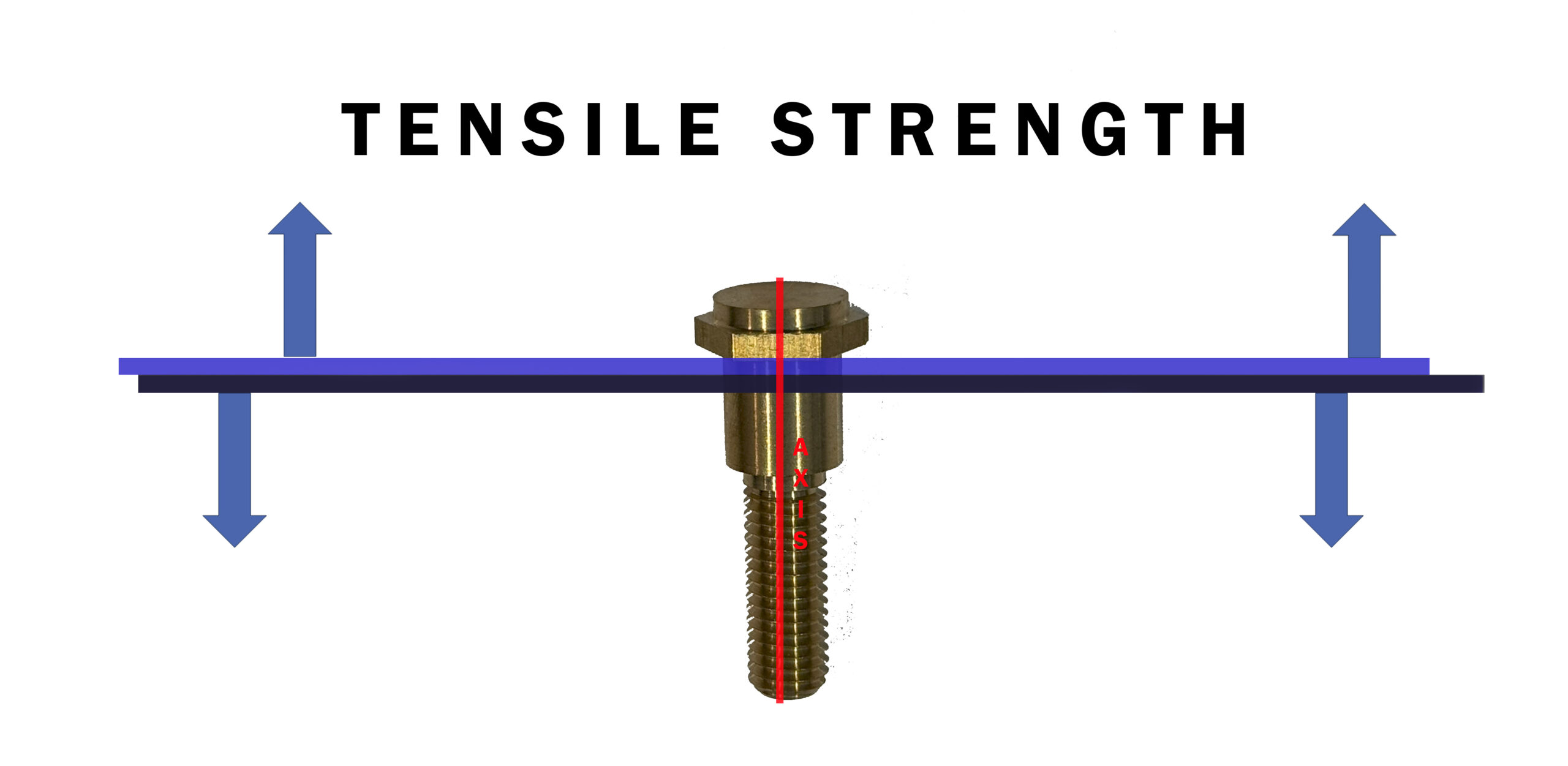

What are some key fastener terms?

At CFI, we a majority of the people that we deal with are engineers. However, we do deal with “civilians” on a regular basis as well. That’s why we’ve put together a nice glossary of fastener terms for you to reference. Many of these are physics terms that are important