OK, we’ve asked the basic questions of what hot forging and cold heading are – now it’s time to get down to the nitty gritty. Which one of these processes should you choose? For fastener engineers, selecting the right manufacturing process can significantly impact product performance, production costs, and lead

cold forming

What is Hot Forging?

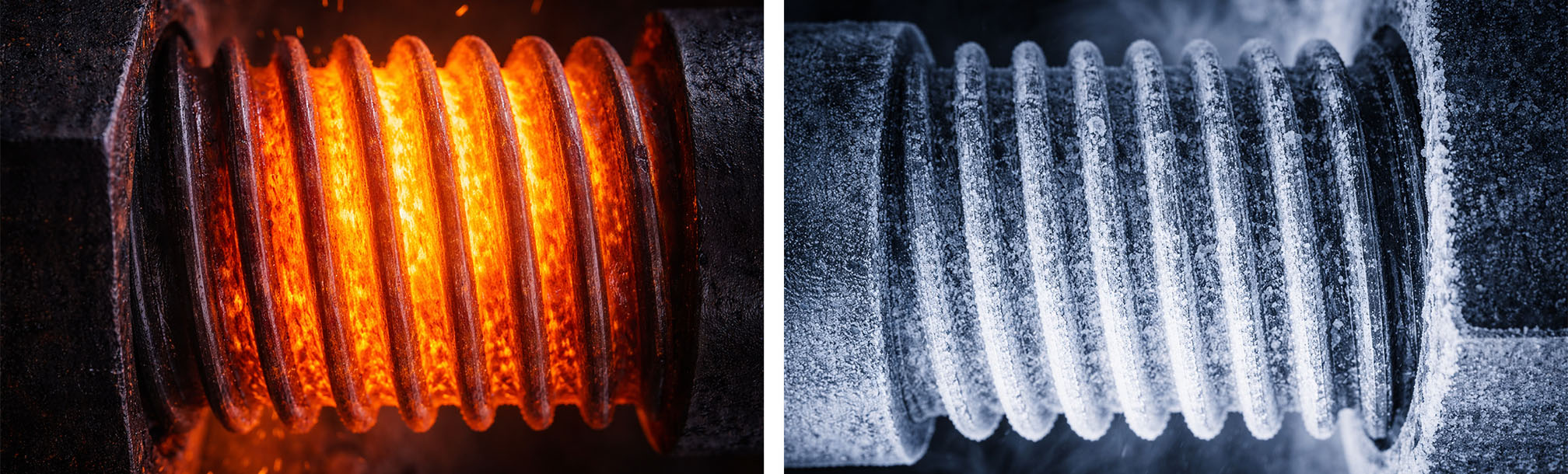

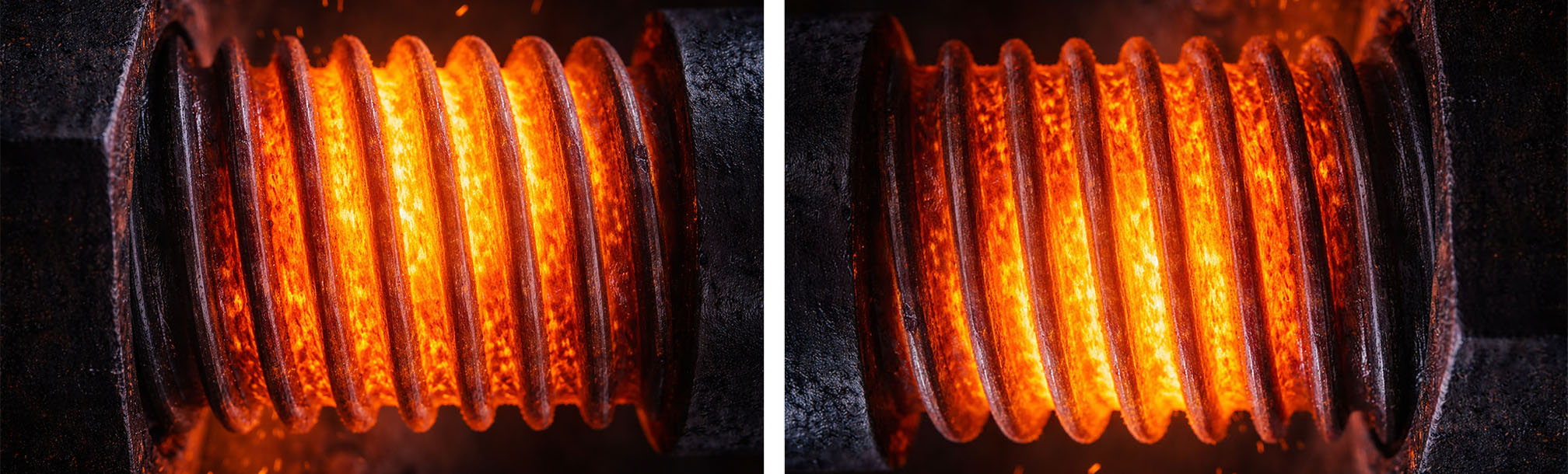

Hot forging represents a critical manufacturing process for fasteners exceeding M36 diameter and for applications involving high-performance materials such as titanium alloys in aerospace applications. A comprehensive understanding of hot forging is essential for informed design decisions in fastener engineering. Technical Definition Hot forging is the plastic deformation of metal

What Is Cold Heading? A Complete Beginner’s Guide for Engineers

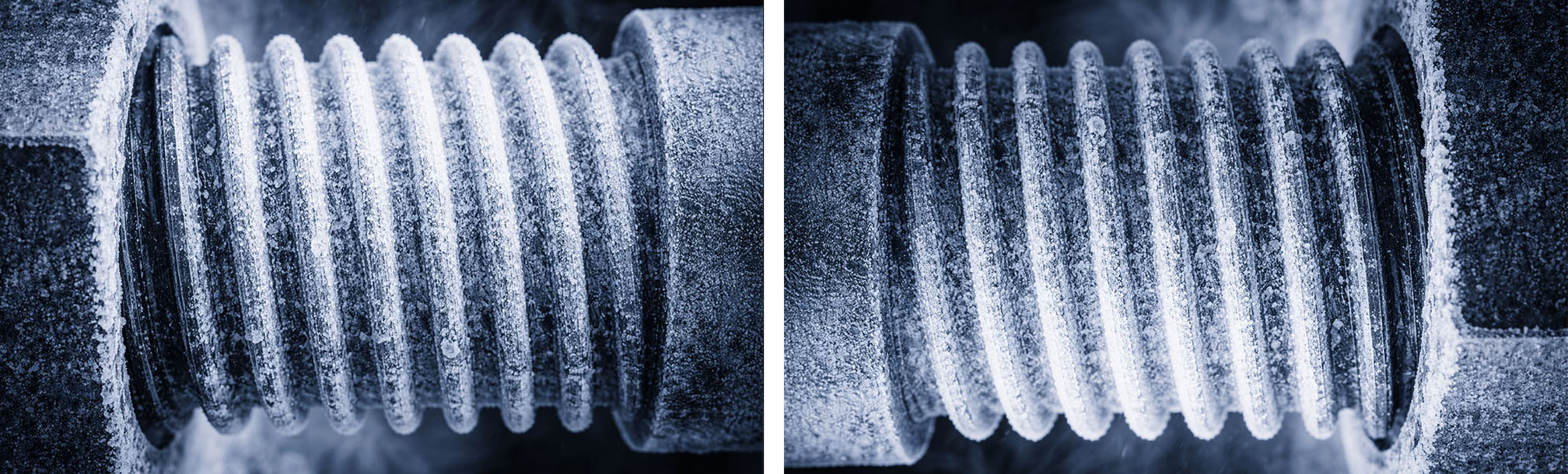

When you’re designing fasteners for potential project, understanding the manufacturing process can significantly impact your design decisions, costs, and product performance. One of these fastener manufacturing processes, cold heading – also called cold forming – is one of the most efficient and reliable manufacturing processes for producing high-strength fasteners and

What is the difference between cold forming and cold heading?

At CFI, we engineer custom screws nuts and bolts every day. One of the methods we use is called Cold Heading or Cold Forming. To answer the basic question, there is no difference between cold forming and cold heading, so the terms are truly interchangeable. The real difference is between