If you’re designing plastic assemblies that need to be taken apart and reassembled, you already understand that standard plastic threads simply won’t cut it. But understanding why threaded inserts are not just beneficial, but actually critical requires looking at the fundamental material science challenges that plastics present for threaded connections.

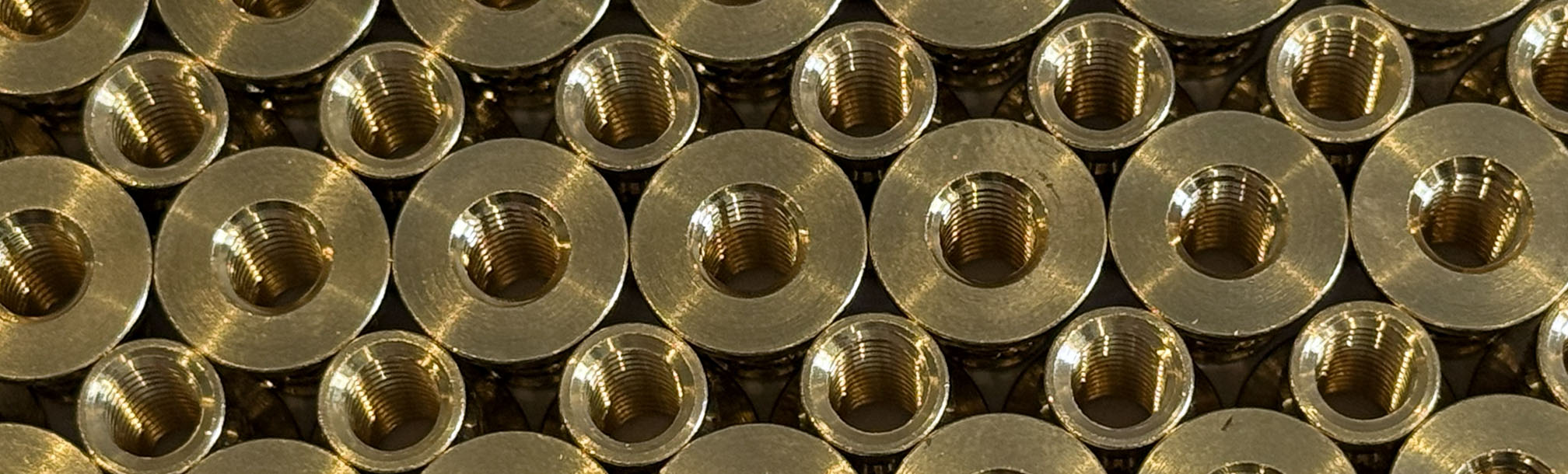

Brass Inserts

How Does Thermal Cycling Affect Threaded Inserts in Automotive Plastics?

If you’re a plastics engineer working on automotive applications, thermal cycling is undoubtedly a four-letter word in your world. After all, it’s one of the most punishing environments your components will face. In addition, it places stress1 on not only your plastic and composite parts, but also places strain on

How Do Inserts Perform in Carbon Fiber Composites?

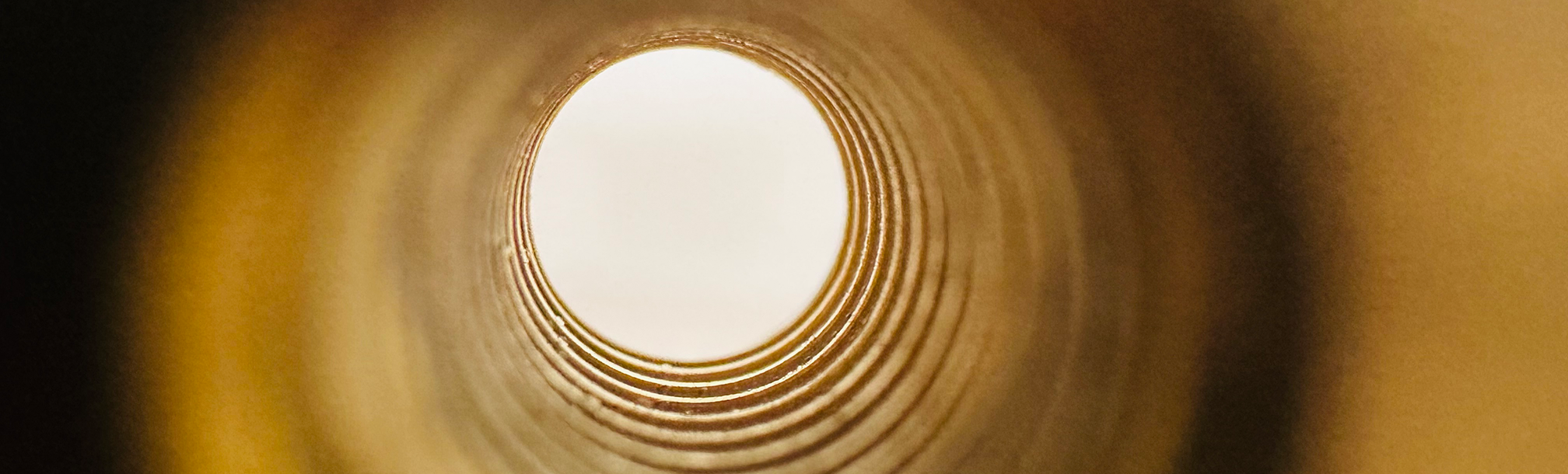

Carbon fiber reinforced polymers (CFRP) have transformed aerospace, automotive, and high-performance applications by delivering exceptional strength-to-weight ratios and fatigue resistance. But how do you create reliable threaded connections in a material that’s fundamentally different from the metals we’ve been fastening for over a century? Threaded inserts. However, their performance in

What Are the Key Differences Between Brass, Steel, and Plastic Threaded Inserts, and When Should You Use Each Material?

When purchasing threaded inserts for plastic assemblies, the material choice directly impacts performance, cost, and reliability. While we’ve litigated this topic before, we keep seeing additional interest in our data, we thought we might provide something a little easier to digest about threaded inserts. Brass absolutely dominates the market. We’re

Choosing the Best Threaded Insert Material: Brass, Steel, or Aluminum?

Threaded inserts are essential in any industry where strong connections are needed, enhancing durability, design flexibility, and load-bearing capacity. Now, the need for the threaded insert is unquestioned. The hard part is deciding the material for the insert. Why? It’s because there are pros and cons for every common threaded

Why Are Threaded Inserts Essential in Household Appliances?

See how the use of exotic materials, plastics and high-stress parts made threaded inserts a vital partner in the Appliance Industry As we move further into the 2020s, every household appliance seems to get more and more complicated. However, one thing remains the same: the need for seemingly simple,

Why Steel Inserts or Aluminum Inserts might be a good alternative to Brass

Here at CFI, we’ve been working with components of all kinds for over three decades, including threaded inserts. Typically, inserts are made from brass, due to the material’s versatility thanks to its position in the material science Goldilocks zone of relative strength, cost, corrosion resistance, machinability, thermal conductivity, and lack

Why Threaded Inserts may be the answer for your injection molding application

In our previous blog, we covered the basics of threaded inserts and more specifically, brass inserts. However, we only touched upon their use in injection molding applications. As we said in our previous blog, injection molding goes hand-in-hand with brass inserts because inserts offer a strengthened connection between plastics and

Why choose threaded inserts for your engineering application?

At CFI, we typically engineer custom screws, nuts and bolts for any application, however, our expertise doesn’t end there. Today we will be going over a component called brass inserts. We’ll answer basic questions like what they are, what they do, why they’re often made of brass. In addition, we’ll

What types of threaded inserts are used in cars?

As a direct supplier to automotive OEMs, CFI and its engineers have a lot of experience with automotive components. While many components have a variety of uses, threaded inserts, in particular, are widely utilized throughout the average car. In this blog, we’ll cover the most common types of inserts and