Carbon fiber reinforced polymers (CFRP) have transformed aerospace, automotive, and high-performance applications by delivering exceptional strength-to-weight ratios and fatigue resistance. But how do you create reliable threaded connections in a material that’s fundamentally different from the metals we’ve been fastening for over a century? Threaded inserts. However, their performance in

Aerospace Components

Comparative Analysis of Zinc vs. Phosphate Coatings: What’s the Best Coating for Industrial Applications

Selecting the coating of a fastener is one of the first and most important decisions that an engineer must make. When making this decision, engineers must consider a myriad of important decisions. These decisions include: environmental conditions, corrosion resistance, temperature resistance, electrical conductivity, durability, and of course, cost of the

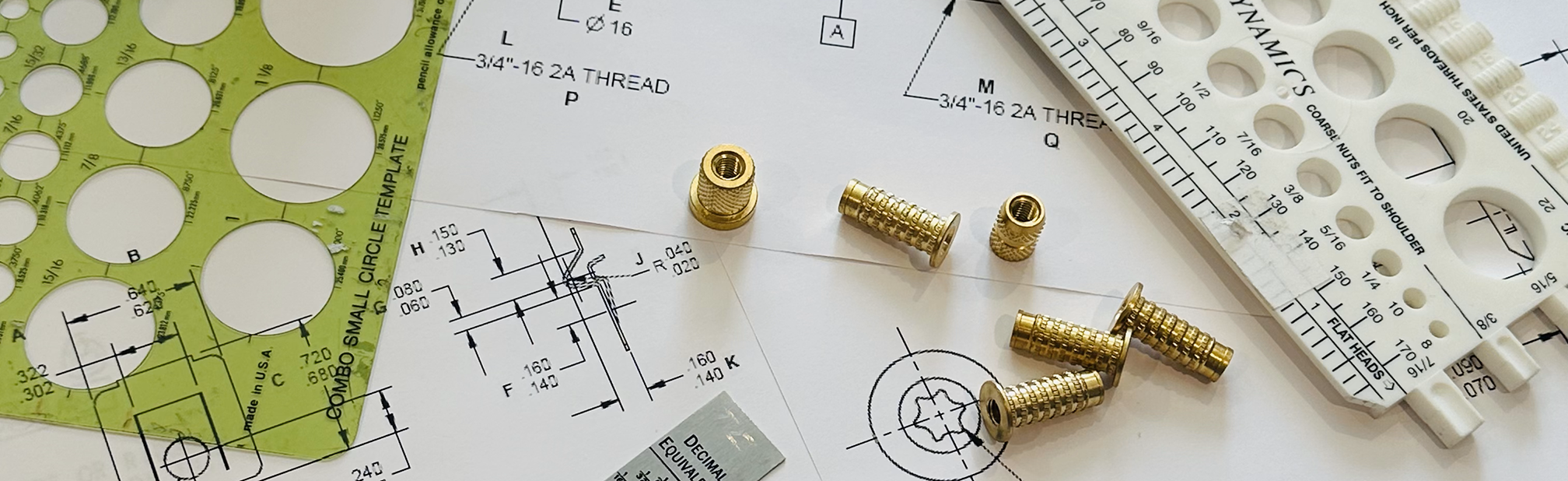

Fastener Material Guide: Comparing Brass, Steel, Aluminum, and Titanium

When designing a new product, thousands of seemingly minute engineering decisions turn into the final product. One of the most important decisions is choosing the fastener materials. While it may not sound like a big decision to a layman, it can have a profound downstream effect on the build quality,

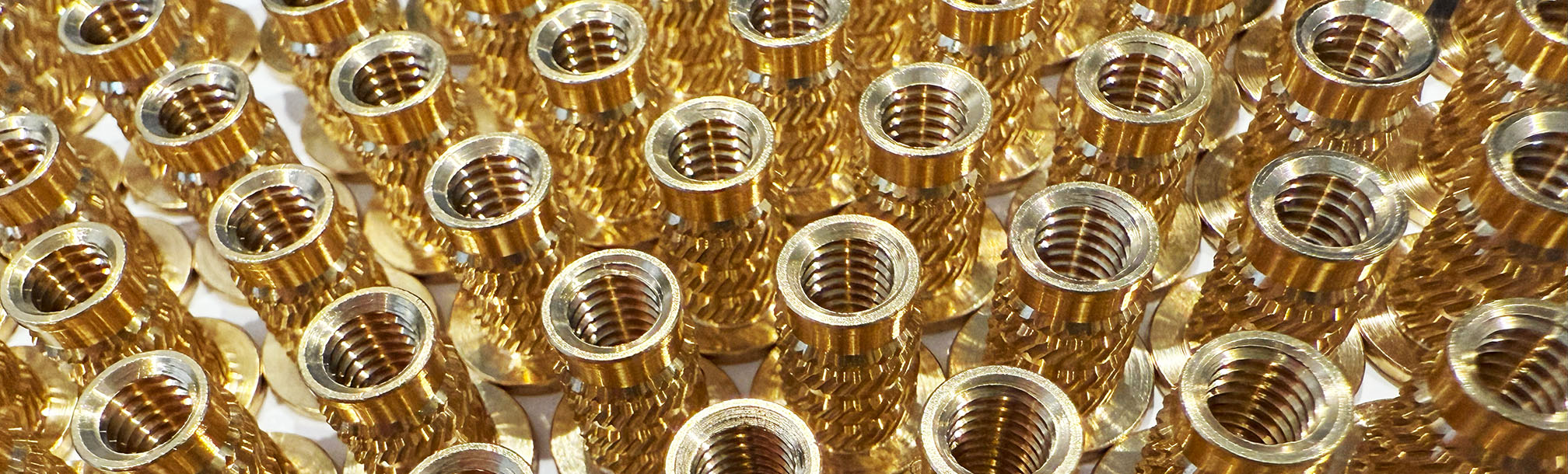

Choosing the Best Threaded Insert Material: Brass, Steel, or Aluminum?

Threaded inserts are essential in any industry where strong connections are needed, enhancing durability, design flexibility, and load-bearing capacity. Now, the need for the threaded insert is unquestioned. The hard part is deciding the material for the insert. Why? It’s because there are pros and cons for every common threaded

As Aluminum Usage Soars, So Does the Need for Reliable Threaded Inserts

Exploring the Rising Need for Threaded Inserts Amid the Increasing Adoption of Aluminum in Modern Manufacturing In 2019, according to the International Aluminum Institute, the automotive industry made up 18% of the world’s total aluminum consumption annually. That number is expected to more than double to as much as 335

How Aerospace Engineers Use Threaded Inserts to Increase Assembly Efficiency

Boosting precision while reducing production costs: The role of threaded inserts in aerospace manufacturing In the aerospace industry, precision, durability, and efficiency are critical in every aspect of design and assembly. Threaded inserts play a significant role in meeting these demands by helping streamline the assembly process while ensuring structural

How Threaded Inserts Boost Strength and Minimize Weight in Aerospace Engineering

Every ounce counts in the aerospace industry. Meanwhile, strength is also at a premium because commercial aircraft like the Boeing 737 have to consistently fly upwards of 500 miles an hour while military aircraft like the F-35A Lightning II typically fly faster than two times the speed of most commercial