In our previous blog, we covered the basics of threaded inserts and more specifically, brass inserts. However, we only touched upon their use in injection molding applications. As we said in our previous blog, injection molding goes hand-in-hand with brass inserts because inserts offer a strengthened connection between plastics and

Plastics

Innovation in Threaded Inserts for Automotive Plastics and Composites

In a world filled with next-generation materials, is there still room for the threaded insert? Even in non-electrified vehicles, weight has grown as safety protocols demand more safety systems. According to NADA, the average weight of a new vehicle sold in the US in 2022 was 4,329 pounds – 1,000

Which Fasteners Work Best in High-Vibration Composite Assemblies?

How to choose the best fasteners for plastic and composite materials in dynamic-load environments You’ll find composite materials in everything from everyday kitchen gadgets to high-performance electronics in cars and airplanes. That’s why engineers in these industries must select fasteners can withstand the intense vibration and dynamic stress that come

Heat-Set vs. Ultrasonic Inserts in Injection Molded Plastics

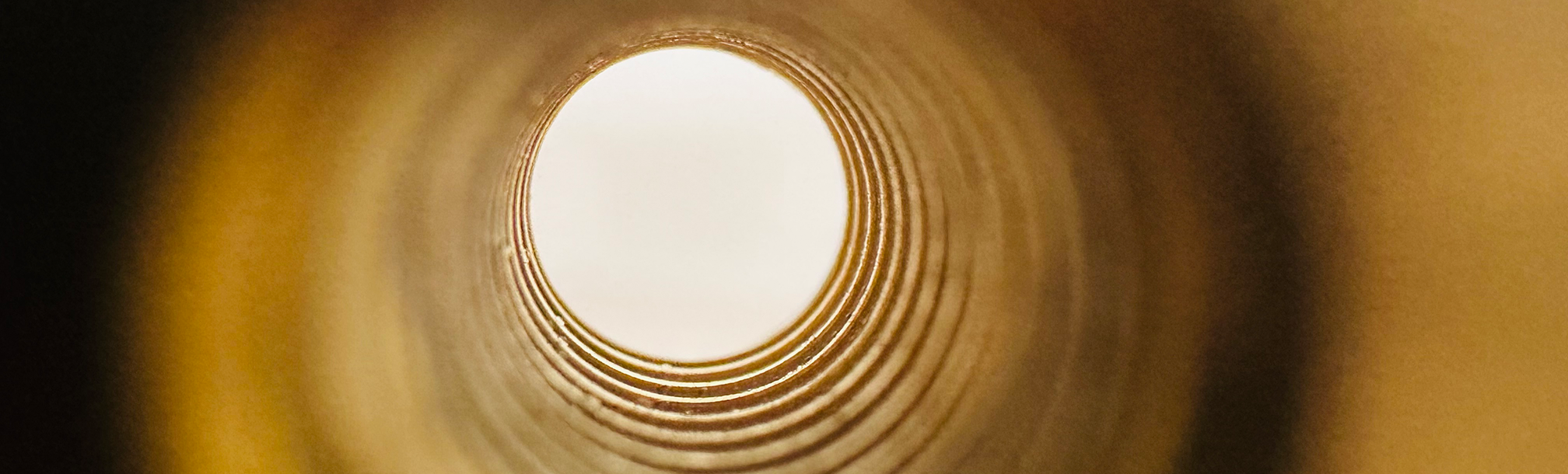

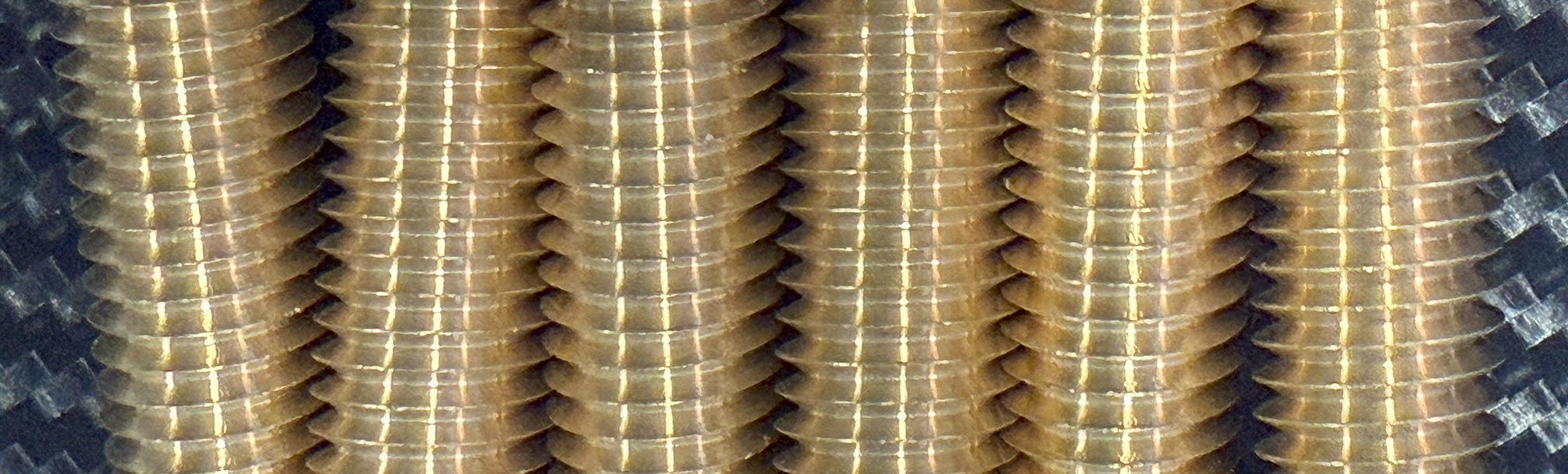

Selecting the Optimal Threaded Insert Seating Method for Industrial Applications If your plastic or composite assemblies require more strength, heat-set and ultrasonic inserts may be the answer. Heat-Set and Ultrasonic Inserts offer and require more pull-out strength than even traditional press-in inserts. Both of these inserts find their strength by

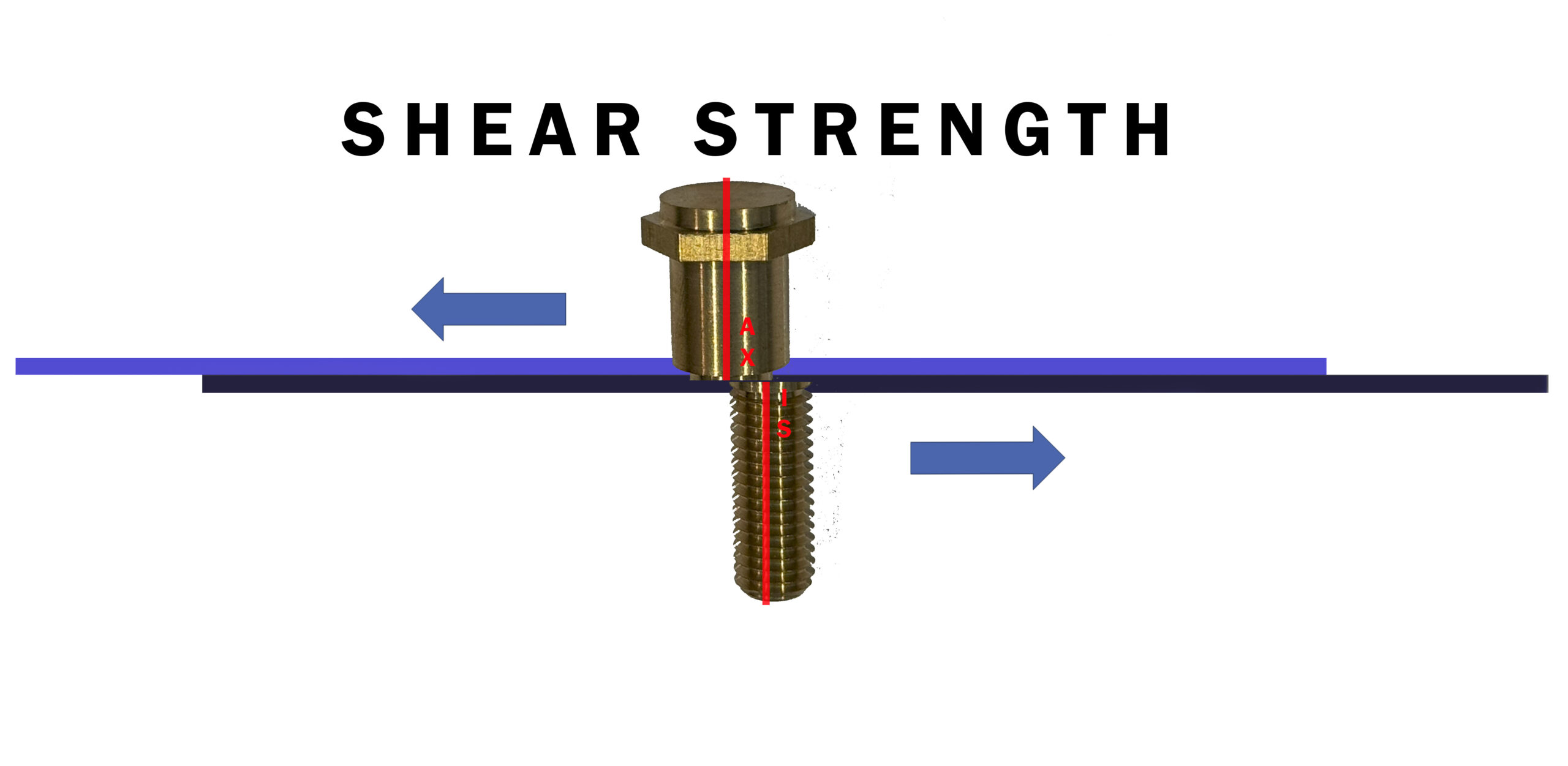

Understanding Shear and Tensile Forces in Composite Fasteners

Why traditional fastener designs may not work Over the last two decades – especially with the advent of heavy batteries in the automotive industry – the race for lightweight and high-performance composite assemblies has taken center stage. These assemblies, typically made from composites like carbon fiber and CFRP have become

Reducing NVH in Automotive Assemblies: The Role of Plastics-Fastener Collaboration

Noise, Vibration and Harshness (NVH) has long been a critical metric for buyers when deciding the overall quality of a vehicle. That’s why we, as fastener and plastics engineers, have to begin thinking about NVH quite literally at the nuts and bolts level. Whether you’re talking about EVs or traditional

Heat Set Inserts vs. Ultrasonic Inserts: Optimizing Fastener Selection for Injection Molded Plastic Assemblies

Fastener selection plays a vital role in determining long-term part integrity, assembly repeatability, and structural performance. Among the most widely used fastening methods for thermoplastics are heat set inserts and ultrasonic inserts. Both methods deliver durable, threaded metal connections, but they differ in how they interact with molded materials and

The Rise of Lightweight Fasteners: Meeting the Demands of EV and Aerospace Sectors

Why Fasteners Matter More Than Ever in Lightweighting Strategies As electric vehicles (EVs) and aerospace applications push the boundaries of lightweight design, every gram counts in modern designs. Engineers in these sectors know that fasteners – while often overlooked – can collectively contribute significant mass to modern designs. With automotive

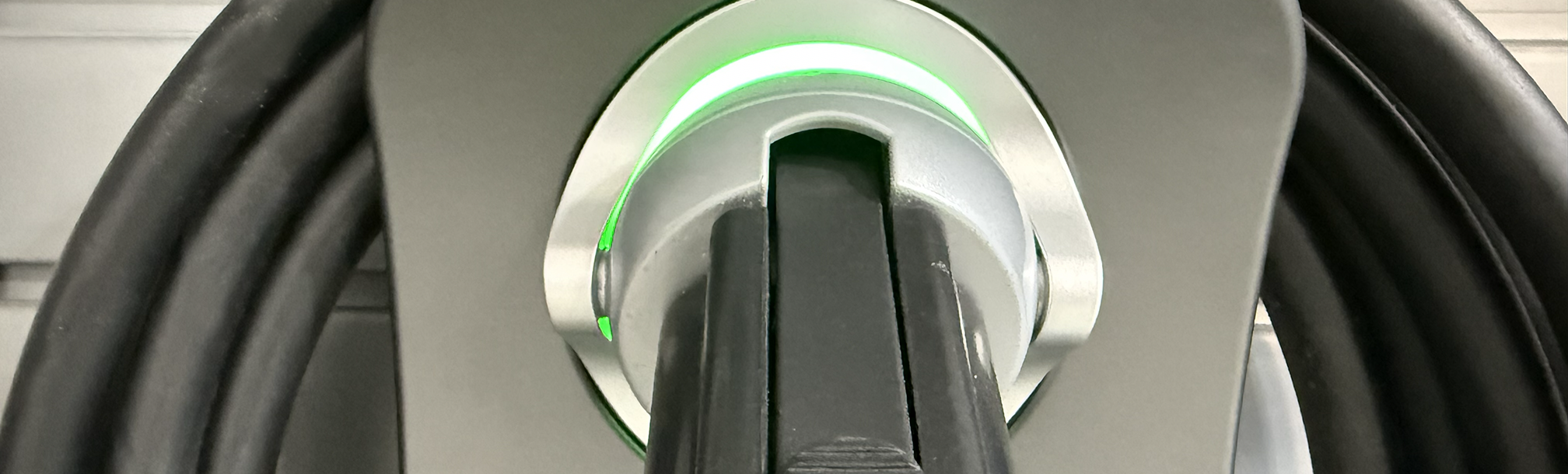

What Inserts Are Used in Plastic Battery Housings and EV Components?

The shift to electric vehicles has quietly become one of the more demanding proving grounds for fastener and insert technology. EV platforms impose requirements that don’t often coexist in conventional automotive design: lightweight plastic housings that must meet structural load requirements, thermal cycling ranges far exceeding traditional underhood environments, vibration

Plastics quickly making their way into automotive engine bays

Over the past decade, plastics and forms of nylon are quickly replacing their ferrous counterparts as the material of choice under the hood of cars and trucks all over the world. How can this be? Conventional wisdom would tell you that the high temperature and high stress environment of an