If you’re designing plastic assemblies that need to be taken apart and reassembled, you already understand that standard plastic threads simply won’t cut it. But understanding why threaded inserts are not just beneficial, but actually critical requires looking at the fundamental material science challenges that plastics present for threaded connections.

Plastics

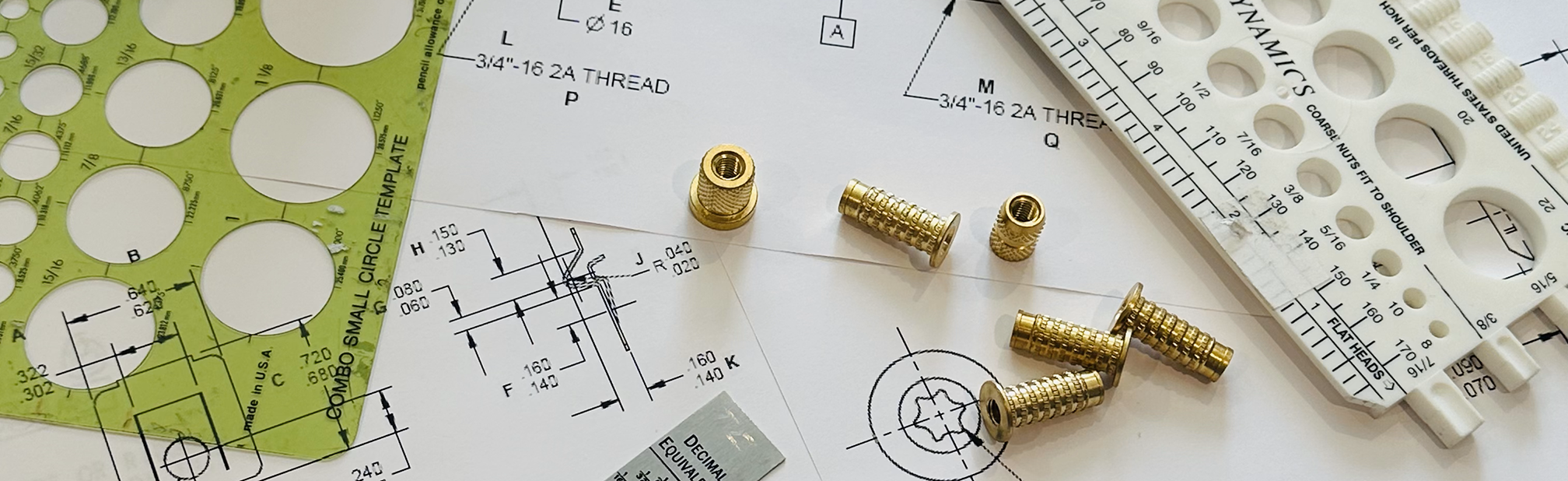

How Do Load Paths Affect the Performance of Threaded Inserts in Plastics?

When plastics engineers think about threaded inserts, the focus often goes straight to the insert itself, looking at attributes such as knurl pattern, installation method and material selection. But here’s what gets overlooked: the insert is only as good as the load path supporting it. A perfectly specified insert installed

How Does Thermal Cycling Affect Threaded Inserts in Automotive Plastics?

If you’re a plastics engineer working on automotive applications, thermal cycling is undoubtedly a four-letter word in your world. After all, it’s one of the most punishing environments your components will face. In addition, it places stress1 on not only your plastic and composite parts, but also places strain on

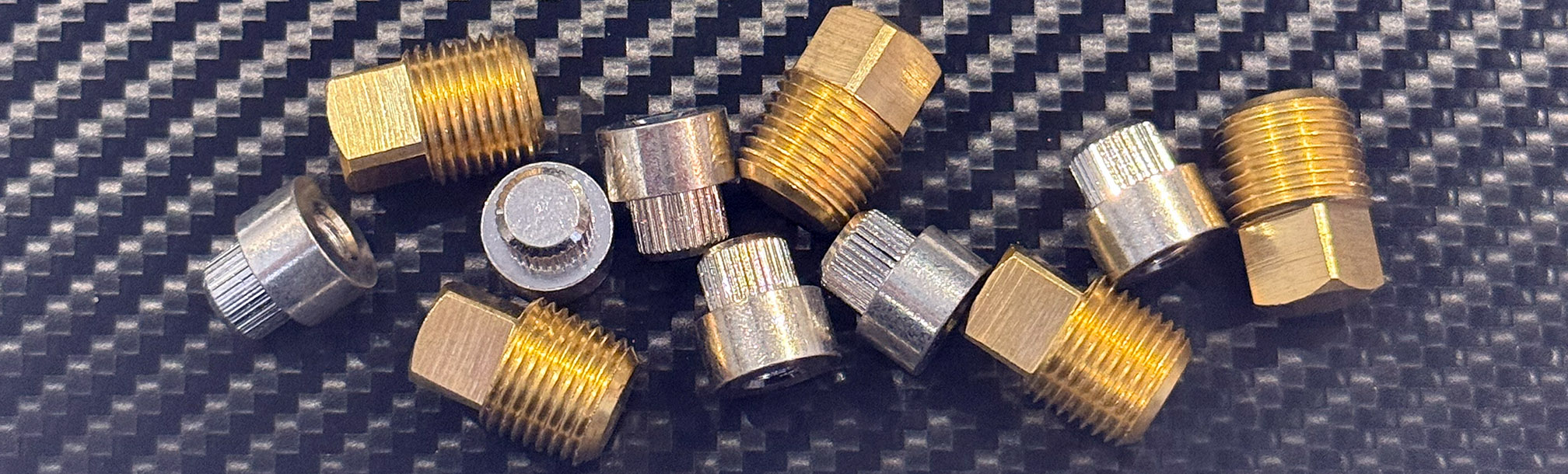

How Do Inserts Perform in Carbon Fiber Composites?

Carbon fiber reinforced polymers (CFRP) have transformed aerospace, automotive, and high-performance applications by delivering exceptional strength-to-weight ratios and fatigue resistance. But how do you create reliable threaded connections in a material that’s fundamentally different from the metals we’ve been fastening for over a century? Threaded inserts. However, their performance in

Reducing Assembly Failures in Automotive Prototyping: Co-Design Strategies for Plastics and Fastener Engineers

As car designers accelerate the integration of lightweight materials into vehicle designs, collaboration between plastics and fastener engineers has become an imperative. Nowhere is this more evident than during the prototyping and pre-production stages, where fastener choices can significantly influence part performance, manufacturability, and long-term durability. When fastener integration is

Understanding Stress Distribution in Fasteners Used for Plastics and Composites

Fasteners used with plastics and composites are subjected to different forces than ones used in metals and other materials. Plastics respond in a completely different manner than metals when subjected to mechanical loads. They exhibit behaviors such as creep, anisotropy, and variable tensile strength depending on polymer type and fiber

Should You Use Self-Tapping Screws in Plastic and Carbon Fiber Assemblies?

Balancing Strength, Speed, and Material Compatibility in Plastics and Carbon Fiber As plastics and composites replace the use of metals in major industries, the question of how best to fasten complex assemblies is more relevant than ever. Self-tapping screws—fasteners that cut their own threads during installation—offer compelling benefits in these

Choosing the Correct Fastener for Composite Materials and Plastics

How to Select Fasteners that Match the Properties of Composites and Plastics Arguably, nothing has revolutionized technological advancement and product design in key industries over the last 75 years like plastics and composites. Advancements in plastic and composite assemblies have driven advancements in key arenas such as aerospace, automotive, medical,

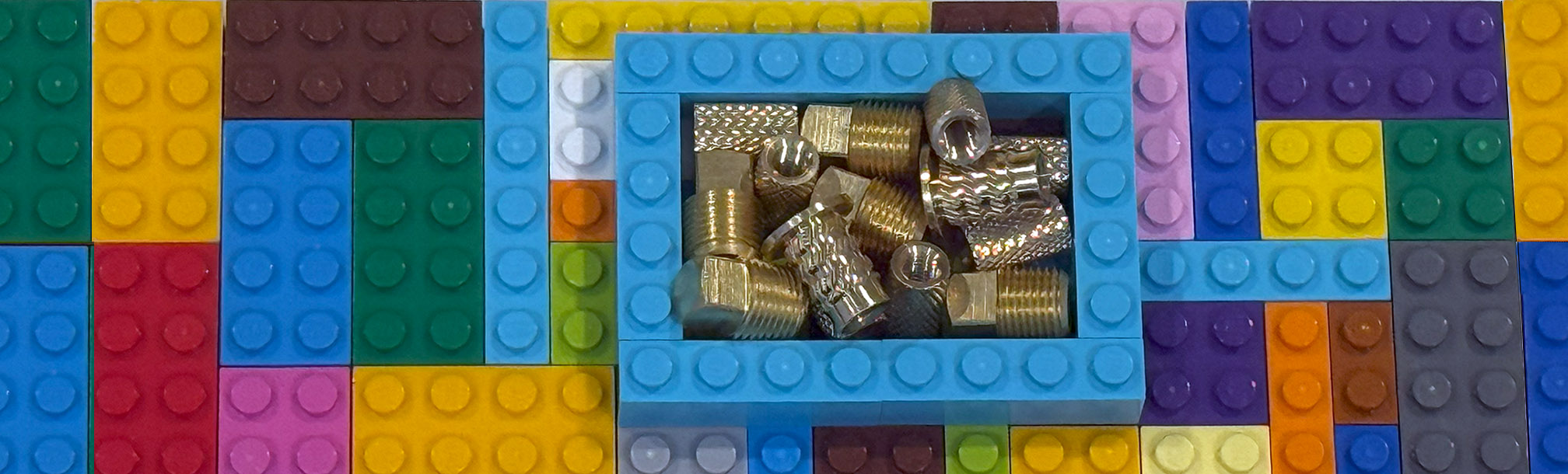

Why Are Threaded Inserts Essential in Household Appliances?

See how the use of exotic materials, plastics and high-stress parts made threaded inserts a vital partner in the Appliance Industry As we move further into the 2020s, every household appliance seems to get more and more complicated. However, one thing remains the same: the need for seemingly simple,

Why Steel Inserts or Aluminum Inserts might be a good alternative to Brass

Here at CFI, we’ve been working with components of all kinds for over three decades, including threaded inserts. Typically, inserts are made from brass, due to the material’s versatility thanks to its position in the material science Goldilocks zone of relative strength, cost, corrosion resistance, machinability, thermal conductivity, and lack