Carbon fiber reinforced polymers (CFRP) have transformed aerospace, automotive, and high-performance applications by delivering exceptional strength-to-weight ratios and fatigue resistance. But how do you create reliable threaded connections in a material that’s fundamentally different from the metals we’ve been fastening for over a century? Threaded inserts. However, their performance in

Composites

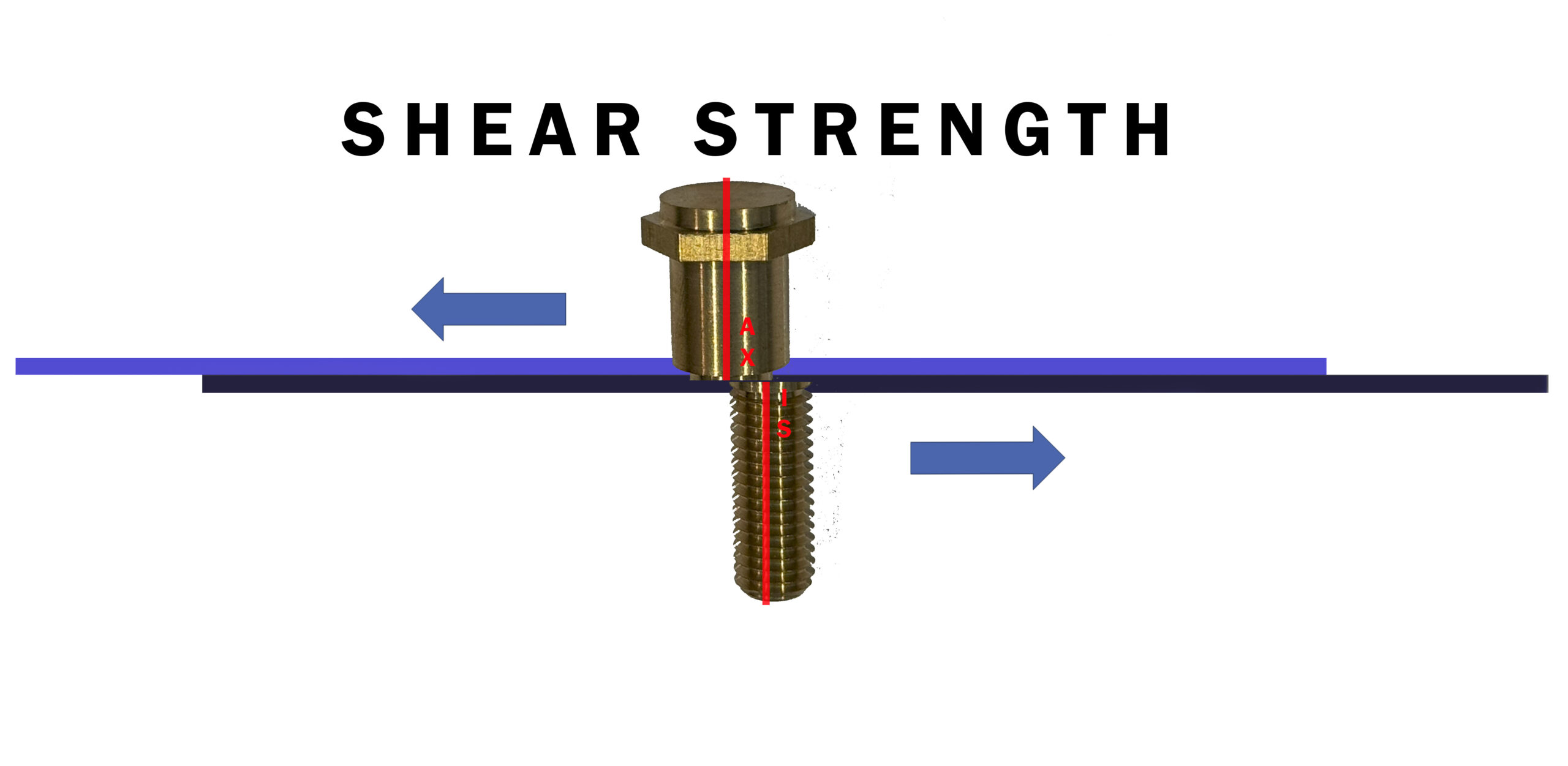

Understanding Shear and Tensile Forces in Composite Fasteners

Why traditional fastener designs may not work Over the last two decades – especially with the advent of heavy batteries in the automotive industry – the race for lightweight and high-performance composite assemblies has taken center stage. These assemblies, typically made from composites like carbon fiber and CFRP have become

Strength and Aesthetics: Fastener Integration Without Marring Injection-Molded Surfaces

How to Conceal Fasteners Without Compromising Design Strength In automotive industry product design, achieving both strength and aesthetics can be especially challenging. While incorporating fasteners are essential to the end design for reliable assembly, they can leave unsightly cosmetic flaws on injection molded surfaces. However, built from the ground-up with

Stainless Steel Fasteners vs. Coated Fasteners in Plastic Assemblies

How to balance Corrosion Resistance and Cost Efficiency for end users When fastener engineers and injection molding engineers work together, projects often start with targeted goals for the component. Two goals that we often work toward with any partner at CFI are corrosion resistance and cost efficiency. With injection molding

The Rise of Lightweight Fasteners: Meeting the Demands of EV and Aerospace Sectors

Why Fasteners Matter More Than Ever in Lightweighting Strategies As electric vehicles (EVs) and aerospace applications push the boundaries of lightweight design, every gram counts in modern designs. Engineers in these sectors know that fasteners – while often overlooked – can collectively contribute significant mass to modern designs. With automotive