Exploring the Rising Need for Threaded Inserts Amid the Increasing Adoption of Aluminum in Modern Manufacturing In 2019, according to the International Aluminum Institute, the automotive industry made up 18% of the world’s total aluminum consumption annually. That number is expected to more than double to as much as 335

Automotive Components

Innovation in Threaded Inserts for Automotive Plastics and Composites

In a world filled with next-generation materials, is there still room for the threaded insert? Even in non-electrified vehicles, weight has grown as safety protocols demand more safety systems. According to NADA, the average weight of a new vehicle sold in the US in 2022 was 4,329 pounds – 1,000

Custom Fasteners vs. Off-the-Shelf Options: Which is Right for You?

When we work with our partners, we see them go through some of the same engineering struggles again and again when they’re considering fasteners. One of the most common challenges manufacturers face is deciding between off-the-shelf fasteners or custom options tailored to their specific project needs. Designing a new product

Reducing NVH in Automotive Assemblies: The Role of Plastics-Fastener Collaboration

Noise, Vibration and Harshness (NVH) has long been a critical metric for buyers when deciding the overall quality of a vehicle. That’s why we, as fastener and plastics engineers, have to begin thinking about NVH quite literally at the nuts and bolts level. Whether you’re talking about EVs or traditional

The Rise of Lightweight Fasteners: Meeting the Demands of EV and Aerospace Sectors

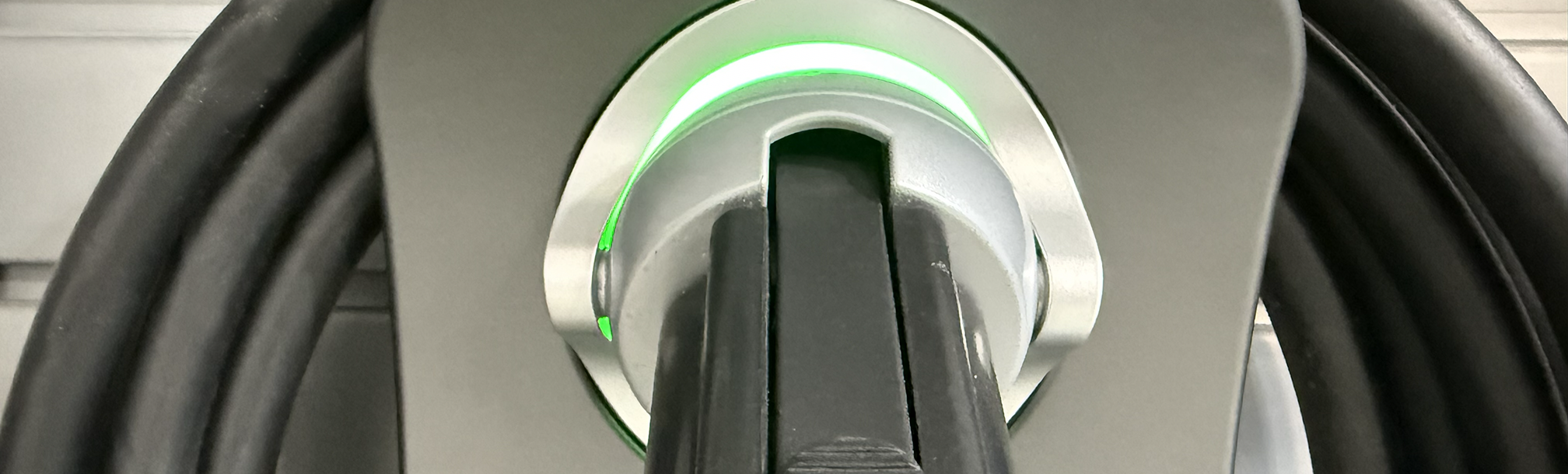

Why Fasteners Matter More Than Ever in Lightweighting Strategies As electric vehicles (EVs) and aerospace applications push the boundaries of lightweight design, every gram counts in modern designs. Engineers in these sectors know that fasteners – while often overlooked – can collectively contribute significant mass to modern designs. With automotive

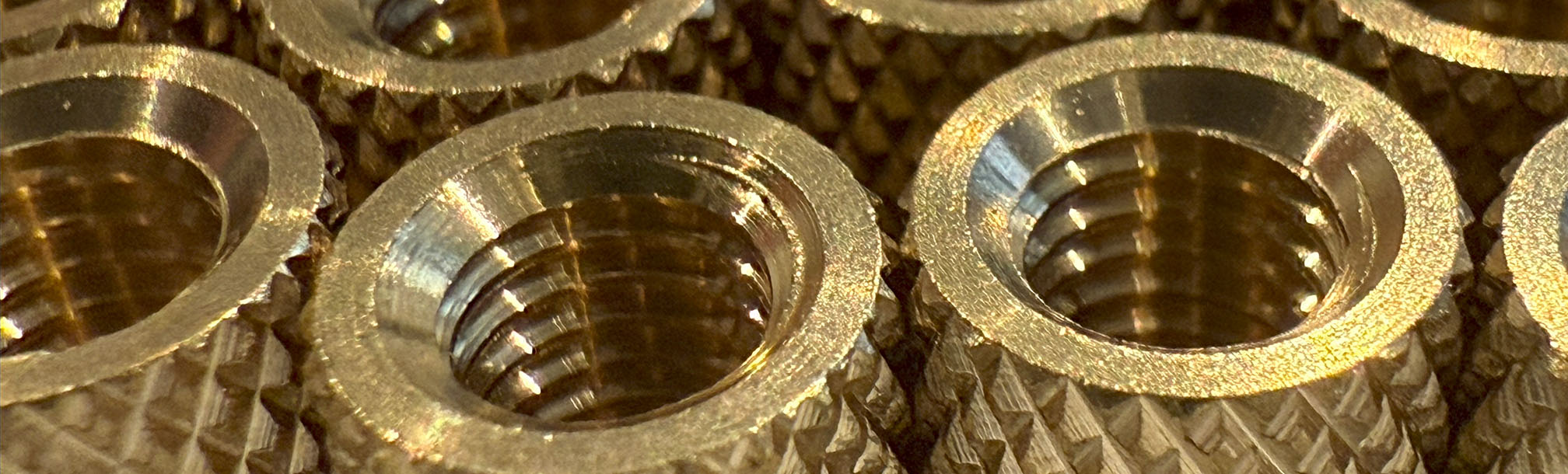

What Inserts Are Used in Plastic Battery Housings and EV Components?

The shift to electric vehicles has quietly become one of the more demanding proving grounds for fastener and insert technology. EV platforms impose requirements that don’t often coexist in conventional automotive design: lightweight plastic housings that must meet structural load requirements, thermal cycling ranges far exceeding traditional underhood environments, vibration

Plastics quickly making their way into automotive engine bays

Over the past decade, plastics and forms of nylon are quickly replacing their ferrous counterparts as the material of choice under the hood of cars and trucks all over the world. How can this be? Conventional wisdom would tell you that the high temperature and high stress environment of an