If you’re designing plastic assemblies that need to be taken apart and reassembled, you already understand that standard plastic threads simply won’t cut it. But understanding why threaded inserts are not just beneficial, but actually critical requires looking at the fundamental material science challenges that plastics present for threaded connections.

Automotive Components

How Does Thermal Cycling Affect Threaded Inserts in Automotive Plastics?

If you’re a plastics engineer working on automotive applications, thermal cycling is undoubtedly a four-letter word in your world. After all, it’s one of the most punishing environments your components will face. In addition, it places stress1 on not only your plastic and composite parts, but also places strain on

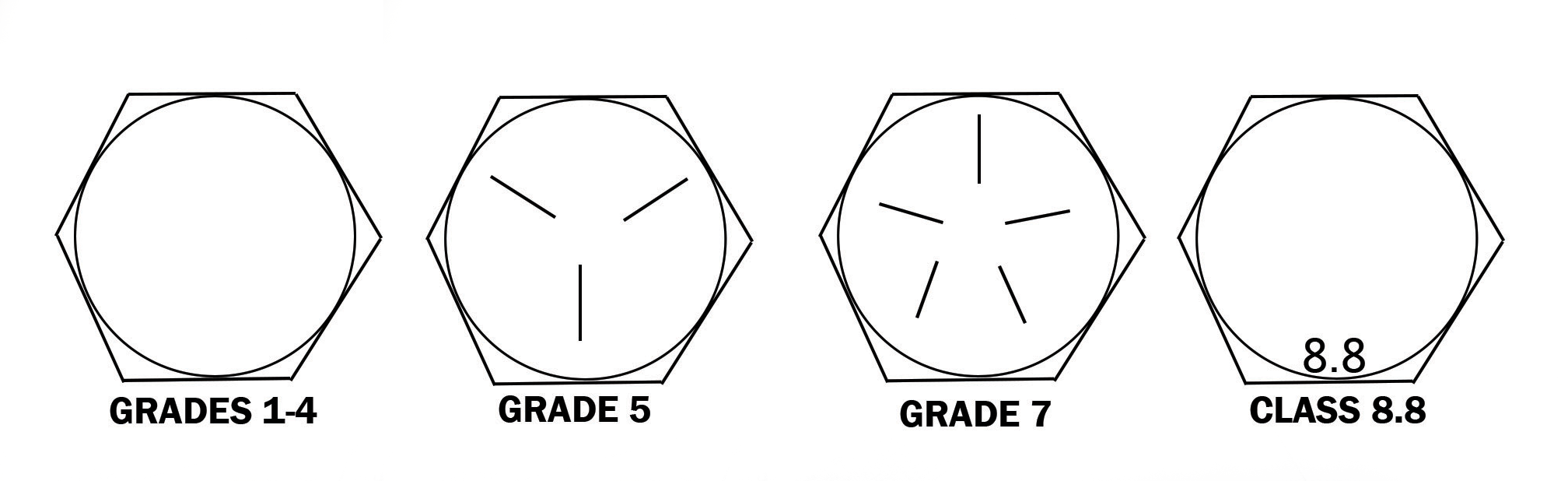

Understanding Automotive Bolt Grades and Classes

How They’re Determined by the SAE, and How They’re Identified by Markings on the Fastener Head Automotive bolted joints operate under demanding cyclic loads, high temperatures, and increasingly lightweight designs. As a result, understanding bolt grades – and the standards behind them-is essential for fastener engineers working in OEM, Tier

How Do Inserts Perform in Carbon Fiber Composites?

Carbon fiber reinforced polymers (CFRP) have transformed aerospace, automotive, and high-performance applications by delivering exceptional strength-to-weight ratios and fatigue resistance. But how do you create reliable threaded connections in a material that’s fundamentally different from the metals we’ve been fastening for over a century? Threaded inserts. However, their performance in

Reducing Assembly Failures in Automotive Prototyping: Co-Design Strategies for Plastics and Fastener Engineers

As car designers accelerate the integration of lightweight materials into vehicle designs, collaboration between plastics and fastener engineers has become an imperative. Nowhere is this more evident than during the prototyping and pre-production stages, where fastener choices can significantly influence part performance, manufacturability, and long-term durability. When fastener integration is

Comparative Analysis of Zinc vs. Phosphate Coatings: What’s the Best Coating for Industrial Applications

Selecting the coating of a fastener is one of the first and most important decisions that an engineer must make. When making this decision, engineers must consider a myriad of important decisions. These decisions include: environmental conditions, corrosion resistance, temperature resistance, electrical conductivity, durability, and of course, cost of the

Fastener Material Guide: Comparing Brass, Steel, Aluminum, and Titanium

When designing a new product, thousands of seemingly minute engineering decisions turn into the final product. One of the most important decisions is choosing the fastener materials. While it may not sound like a big decision to a layman, it can have a profound downstream effect on the build quality,

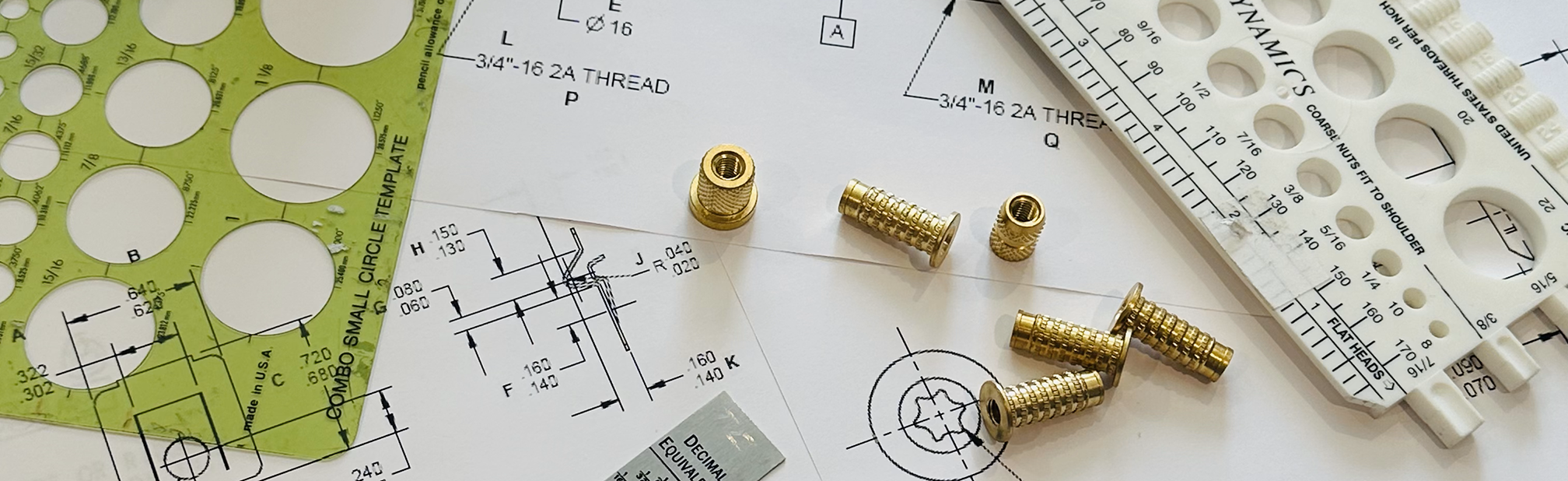

Choosing the Best Threaded Insert Material: Brass, Steel, or Aluminum?

Threaded inserts are essential in any industry where strong connections are needed, enhancing durability, design flexibility, and load-bearing capacity. Now, the need for the threaded insert is unquestioned. The hard part is deciding the material for the insert. Why? It’s because there are pros and cons for every common threaded

What types of threaded inserts are used in cars?

As a direct supplier to automotive OEMs, CFI and its engineers have a lot of experience with automotive components. While many components have a variety of uses, threaded inserts, in particular, are widely utilized throughout the average car. In this blog, we’ll cover the most common types of inserts and

What are threaded inserts used for in the automotive industry?

Threaded inserts are utilized to strengthen and add threads to all kinds of materials, from plastics, to composites, to woods. But, how are they utilized in the automotive sector? Inserts have found their way into cars, trucks and SUVs for a wide range of uses, from interior components, to the