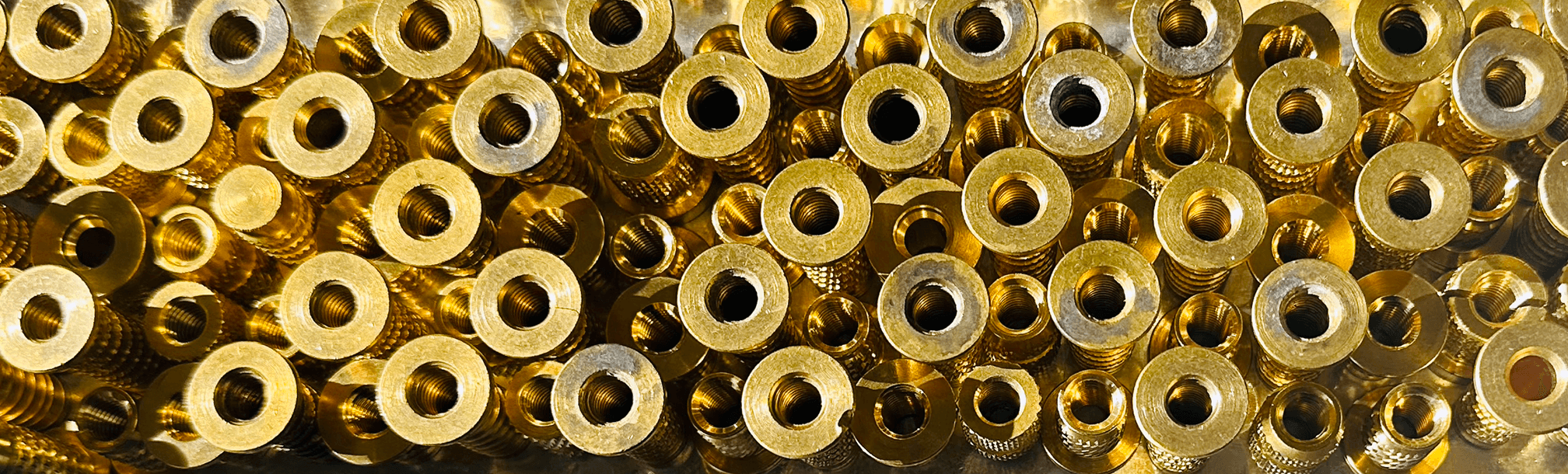

Here at CFI, we’ve been working with components of all kinds for over three decades, including threaded inserts. Typically, inserts are made from brass, due to the material’s versatility thanks to its position in the material science Goldilocks zone of relative strength, cost, corrosion resistance, machinability, thermal conductivity, and lack

CFI Editor

Why Threaded Inserts may be the answer for your injection molding application

In our previous blog, we covered the basics of threaded inserts and more specifically, brass inserts. However, we only touched upon their use in injection molding applications. As we said in our previous blog, injection molding goes hand-in-hand with brass inserts because inserts offer a strengthened connection between plastics and

Why choose threaded inserts for your engineering application?

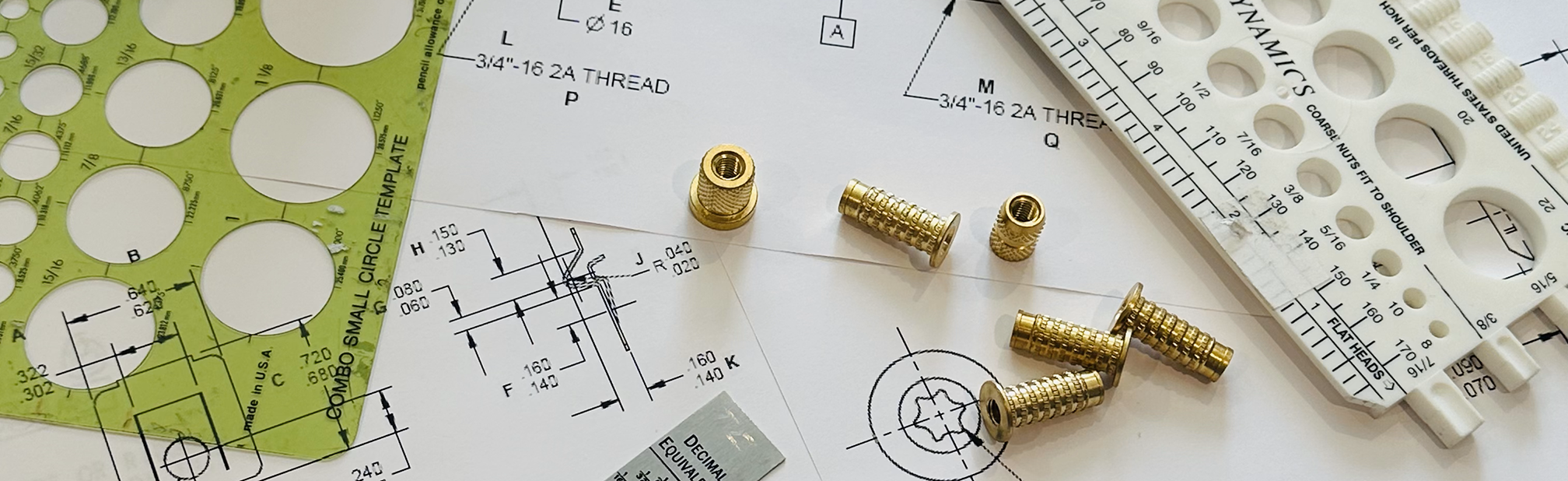

At CFI, we typically engineer custom screws, nuts and bolts for any application, however, our expertise doesn’t end there. Today we will be going over a component called brass inserts. We’ll answer basic questions like what they are, what they do, why they’re often made of brass. In addition, we’ll

What types of threaded inserts are used in cars?

As a direct supplier to automotive OEMs, CFI and its engineers have a lot of experience with automotive components. While many components have a variety of uses, threaded inserts, in particular, are widely utilized throughout the average car. In this blog, we’ll cover the most common types of inserts and

What are threaded inserts used for in the automotive industry?

Threaded inserts are utilized to strengthen and add threads to all kinds of materials, from plastics, to composites, to woods. But, how are they utilized in the automotive sector? Inserts have found their way into cars, trucks and SUVs for a wide range of uses, from interior components, to the

As Aluminum Usage Soars, So Does the Need for Reliable Threaded Inserts

Exploring the Rising Need for Threaded Inserts Amid the Increasing Adoption of Aluminum in Modern Manufacturing In 2019, according to the International Aluminum Institute, the automotive industry made up 18% of the world’s total aluminum consumption annually. That number is expected to more than double to as much as 335

Innovation in Threaded Inserts for Automotive Plastics and Composites

In a world filled with next-generation materials, is there still room for the threaded insert? Even in non-electrified vehicles, weight has grown as safety protocols demand more safety systems. According to NADA, the average weight of a new vehicle sold in the US in 2022 was 4,329 pounds – 1,000

How Aerospace Engineers Use Threaded Inserts to Increase Assembly Efficiency

Boosting precision while reducing production costs: The role of threaded inserts in aerospace manufacturing In the aerospace industry, precision, durability, and efficiency are critical in every aspect of design and assembly. Threaded inserts play a significant role in meeting these demands by helping streamline the assembly process while ensuring structural

How Threaded Inserts Boost Strength and Minimize Weight in Aerospace Engineering

Every ounce counts in the aerospace industry. Meanwhile, strength is also at a premium because commercial aircraft like the Boeing 737 have to consistently fly upwards of 500 miles an hour while military aircraft like the F-35A Lightning II typically fly faster than two times the speed of most commercial

Which Fasteners Work Best in High-Vibration Composite Assemblies?

How to choose the best fasteners for plastic and composite materials in dynamic-load environments You’ll find composite materials in everything from everyday kitchen gadgets to high-performance electronics in cars and airplanes. That’s why engineers in these industries must select fasteners can withstand the intense vibration and dynamic stress that come