When purchasing threaded inserts for plastic assemblies, the material choice directly impacts performance, cost, and reliability. While we’ve litigated this topic before, we keep seeing additional interest in our data, we thought we might provide something a little easier to digest about threaded inserts.

Brass absolutely dominates the market. We’re talking on the level of 90 to 95% of all inserts. That said, steel, aluminum, and plastic inserts each have specific applications where they’re the superior choice. Here’s what you need to know to specify the right material for your application.

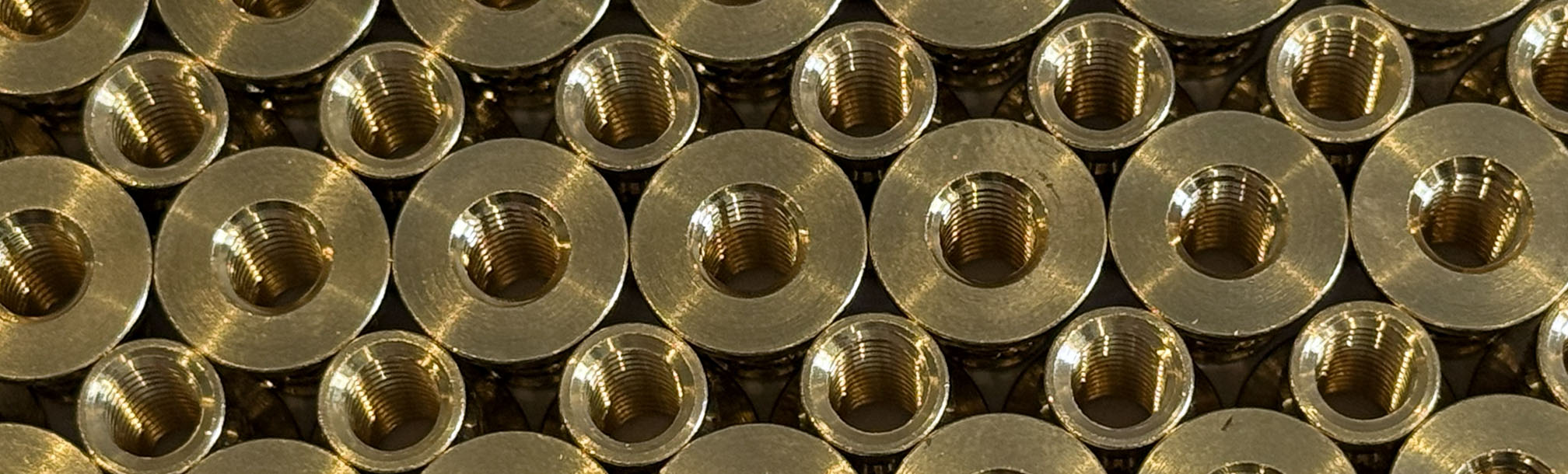

Brass Threaded Inserts: The Default Choice

Brass offers the best balance of performance and cost for most applications.

Key Benefits

Corrosion Resistance: Brass naturally resists corrosion in moisture, chemicals, and many industrial environments. It withstands potable water systems and moderate marine environments (brackish water, slow-moving seawater) depending on alloy.

Thermal Performance: Excellent thermal conductivity makes brass ideal for applications with temperature changes or heat dissipation requirements, including electronics.

Electrical Conductivity: Brass provides reliable electrical connections when conductivity is needed.

Strength and Durability: Brass offers strong threads that withstand significant torque and repeated assembly/disassembly cycles.

Cost-Effective: Brass provides the best value for standard applications, balancing performance with reasonable pricing.

Best Applications for Brass

- Electronics and electrical assemblies

- Marine hardware (moderate environments)

- Plumbing fixtures and water systems

- General industrial applications

- Temperature-cycling environments

- Cost-sensitive projects requiring reliable performance

Limitations

- Lower strength than steel (though sufficient for most applications)

- Not suitable for food contact or medical applications (due to lead content in traditional brass)

- Temperature limits below stainless steel (though adequate for plastic assembly temperatures)

Steel Threaded Inserts: Maximum Performance

Stainless steel inserts provide superior strength and specialized corrosion resistance but cost 40-60% more than brass, depending on market conditions and alloy.

Key Benefits

Superior Strength: Steel handles higher torque loads and stress than brass, preventing thread deformation in demanding applications.

Specialized Corrosion Resistance: Grade 316 stainless excels in aggressive marine environments (fast-moving seawater). Steel resists petroleum products and many acids.

Food and Medical Compliance: 300-series stainless steels are widely used in food-processing an medical applications due to their corrosion resistance and cleanability, subject to applicable regulatory standards.

High Temperature Capability: Withstands higher temperatures than brass (though plastic substrates limit this advantage).

Best Applications for Steel

- High-stress, high-torque applications

- Food and beverage equipment

- Medical devices and pharmaceutical equipment

- Aggressive chemical environments

- Severe marine conditions

- Applications requiring non-magnetic properties

Limitations

- 40-60% higher cost than brass depending on alloy

- Hardness can damage soft plastics during installation

- Some grades vulnerable to crevice or pitting corrosion in specific environments

Aluminum Threaded Inserts: Lightweight Performance

Aluminum inserts are 70% lighter than brass, making them valuable for weight-critical applications.

Key Benefits

Exceptional Weight Savings: 70% lighter than brass, critical for aerospace and automotive applications where weight directly impacts fuel efficiency and performance.

Thermal Conductivity: Excellent heat dissipation for engine components and thermal management systems.

Corrosion Resistance: Forms protective oxide layer providing good resistance in many environments.

Recyclability: Ideal for sustainability initiatives and environmental goals.

Non-Magnetic: Suitable where magnetic interference must be avoided.

Best Applications for Aluminum

- Aerospace components

- Automotive lightweighting (especially electric vehicles)

- Heat dissipation applications

- Sustainability-focused projects

- Non-magnetic requirements

Limitations

- Lower strength and fatigue resistance than brass or steel

- Higher material cost than brass (though lighter weight can offset this)

- Higher thermal expansion than brass or steel

- Risk of galvanic corrosion when contacting carbon fiber or dissimilar metals

Plastic Threaded Inserts: Specialized Applications

Plastic inserts serve niche applications where their unique properties justify significant strength trade-offs.

Key Benefits

Chemical Resistance: Materials like PVC, PTFE, or nylon withstand specific chemicals that corrode metal.

Electrical Isolation: Complete electrical isolation eliminates galvanic corrosion risk.

Weight Reduction: Lighter than any metal alternative.

No Thermal Bridging: Maintains thermal insulation without metal heat paths.

Best Applications for Plastic

- Specific chemical environments

- Electrical isolation requirements

- Thermal insulation applications

- Ultra-low-load applications

- Pipe and plumbing fittings (plastic-to-plastic)

Limitations

- Significantly lower strength than metal

- Subject to creep and stress relaxation under sustained loads

- Limited temperature range

- Poor reusability with repeated assembly/disassembly

Material Selection Guide

Choose Brass When:

- Standard performance meets requirements

- Cost-effectiveness is important

- Corrosion resistance needed for typical environments

- Electrical or thermal conductivity beneficial

Choose Steel When:

- Maximum strength and torque capacity required

- Food contact or medical compliance needed

- Aggressive chemical or marine environment

- Repeated high-stress cycling expected

- Budget allows for 40-60% premium over brass

Choose Aluminum When:

- Weight reduction is critical (aerospace, automotive)

- Heat dissipation important

- Sustainability/recyclability prioritized

- Weight savings justify higher material cost

Choose Plastic When:

- Chemical compatibility requires non-metal

- Electrical isolation essential

- Thermal insulation needed

- Loads and torques minimal

- Very limited applications

Purchasing Recommendations

Start with brass unless you have specific requirements that mandate another material. Brass delivers reliable performance at the best value for the vast majority of applications.

Upgrade to steel only when you need maximum strength, food/medical compliance, or specialized corrosion resistance. The cost premium is justified only when these requirements are genuine.

Select aluminum when weight reduction provides measurable value (fuel efficiency, performance, payload capacity) that offsets higher material costs.

Choose plastic only for niche applications where chemical compatibility or electrical isolation exclude metal options and strength requirements are minimal.

The key is matching material to actual requirements. Over-specifying steel for standard applications wastes budget, while under-specifying brass for high-stress applications risks field failures. Honest assessment of loads, environment, regulatory requirements, and budget constraints leads to the right material choice.

Understanding these differences allows you to specify the optimal insert material from the start, avoiding both unnecessary costs and performance failures.

Where does CFI fit in?

At CFI, we offer a wide range of high-performance threaded inserts and fasteners designed for composites and plastics. Contact our team at 847-918-0333 or sales@componentsforindustry.com to learn how we can support your next engineering project.