At CFI, we a majority of the people that we deal with are engineers. However, we do deal with “civilians” on a regular basis as well. That’s why we’ve put together a nice glossary of fastener terms for you to reference. Many of these are physics terms that are important strength metrics for fasteners that are especially easy to get confused. There are also simple fastener industry terms that make it easier for you to speak in “our” language as you get to know us.

Remember that at CFI, it’s always our job to make the journey easier for you. That’s one of our customer service mantras, so we wanted you to know some basic terminology from the fastener world.

Breakaway Torque

This term is for the torque required to begin reverse rotation in a locking fastener and its mating thread that has not been seated. Over time, this will actually change as the fastener is used and the threads wear and break in. This wearing effect is also known as “1st Off” torque, “5th Off” torque, etc.

Breakloose Torque

This term is used for the amount of torque required to start the disassembly of an axially loaded fastener from reverse rotation and clamp load only.

Ductile

A material capable of being stretched and drawn out into wire before breaking

Installation Torque

In simple terms, Installation Torque is the amount of torque required to properly install a fastener into a material or assembly without damaging the mating material. More specifically, this is the highest reading indicated by a torque measuring device while the screw or nut is being fully engaged but prior to any axial loading.

Isotropic

A material with the same values of strength and stiffness when measured in any direction throughout that material. Examples of isotropic substances are metals and fasteners made from metals. Meanwhile substances made from plastics and carbon fiber are not isotropic.

Locking Torque

Locking torque is a fastener’s overall resistance to rotation. This is a common measure of performance for self-locking fasteners such as self-locking bolts, nuts and split-lock washers. Locking torque is a pullout torque parameter and is measured in inch-pounds (in-lbs), newton-meters (Nm), and similar twist metrics.

Shear Strength

Shear strength is the ability of a fastener to withstand the load at right angles across the shaft of the fastener. Shear force acts perpendicular to the fixing connection, cutting like scissors. A fastener’s shear strength is its ability to withstand said forces.

Self-Tapping Screw Creep

Self-tapping screw creep is the process where a female thread begins to weaken and relax due to stress from overtightening. Misalignment, cracking, thread fracture and loosening may result due to excess tightening torque (1). This creep can occur in female threads in plastics and metals, wherever overtightening occurs.

OD (Outside Diameter)

The OD of a component is its measured diameter of its outermost edge. The difference between the OD and the ID (Inside Diameter) is the wall thickness of the component.

Pullout Resistance

Pullout Resistance is the force required to extract a fastener, anchor or insert from the material that it’s installed. While pullout resistance and pullout torque related, they are not the same. However, pullout resistance and pullout strength are interchangeable terms. This metric is measured in Pounds and Newtons

Pullout Torque

Pullout Torque (POT) is a parameter of screw fixation strength. In other words – what is the rotational torque required to unscrew a fastener. Normally, this metric is measured in inch-pounds (in-lbs) or newton-meters (Nm). Think of pullout torque as working ‘with’ the threads because there is a twist action with rotational force.

Pullout Strength

Pullout Strength (POS) is related to pullout torque, but different. POS refers to the force required to pull a fastener directly out of, or even through, the female threads. This metric is measured in pounds (lbs), newtons (N) and similar units. Think of pullout strength as breaking the threads because you are extracting the fastener with a direct, linear force. The POS of a fastener is influenced by multiple factors including the diameter, design of the threading, density, and depth/thickness of the mating material.

Seating Torque

Seating torque is the torque applied a fastener to induce a compressive load under the head to induce a compressive load during the initial phase of tightening. This value is measured in inch-pounds (in-lb)

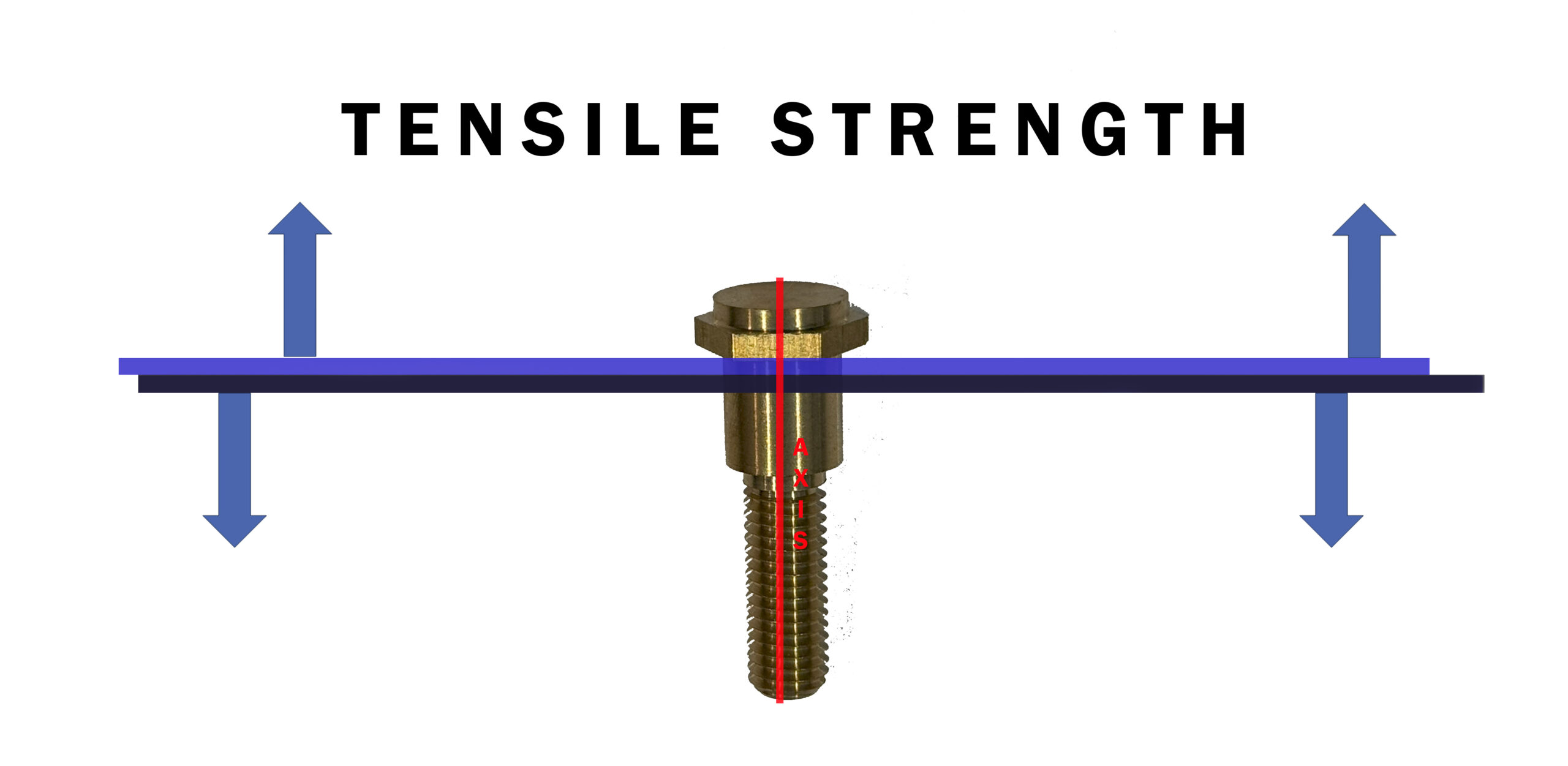

Tensile Strength

Tensile strength is the maximum amount of pulling or stretching stress across its axis that a material can withstand without failure. This is a key property used to show the strength of materials including metals, polymers and composites. Tensile strength is typically measured in Pounds per Square Inch (psi) and Pascals (Pa).

These are just some of the terms that you might encounter as you get into the fastener industry. If you have any questions, please feel free to send them our way and we would be happy to answer them, or, in the future, add to this list.

Where does CFI fit in?

For over 30 years, Components for Industry has been a worldwide provider in industrial components such as brass inserts for a wide number of industries like Automotive, Aerospace, Appliance and Heavy Industrial. If you want more information about CFI, our industrial components or our custom design process, contact us at 847-918-0333 or sales@componentsforindustry.com.

1. ‘Toray’. Miscellaneous (Screw Fastening and Self-Tapping). Obtained from https://www.plastics.toray/technical/torelina/tec_027.html